Advanced Technology AOB VS GOB

Views: 4225

Author: Scarlett

Publish Time: 2022-08-17

Origin: Site

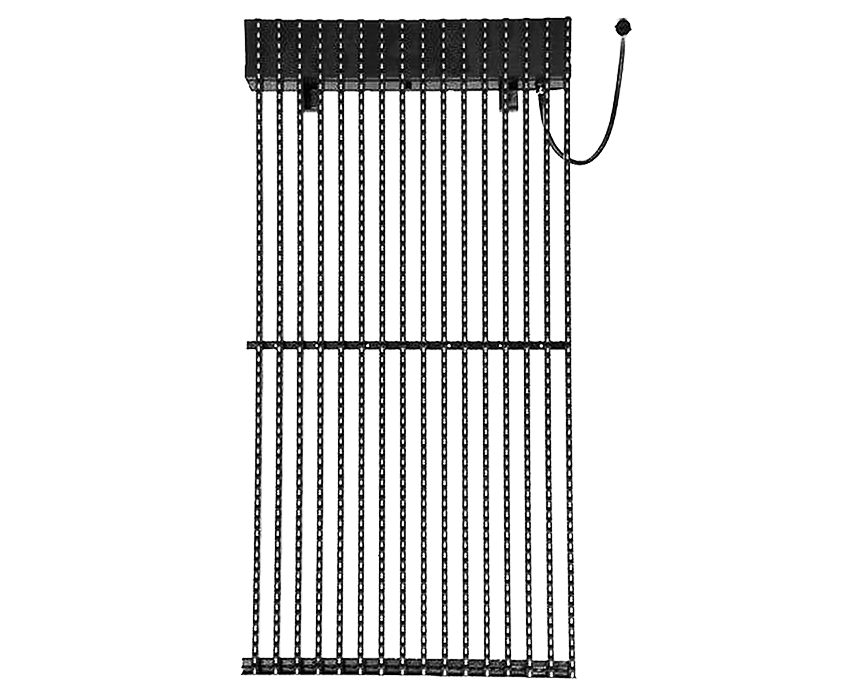

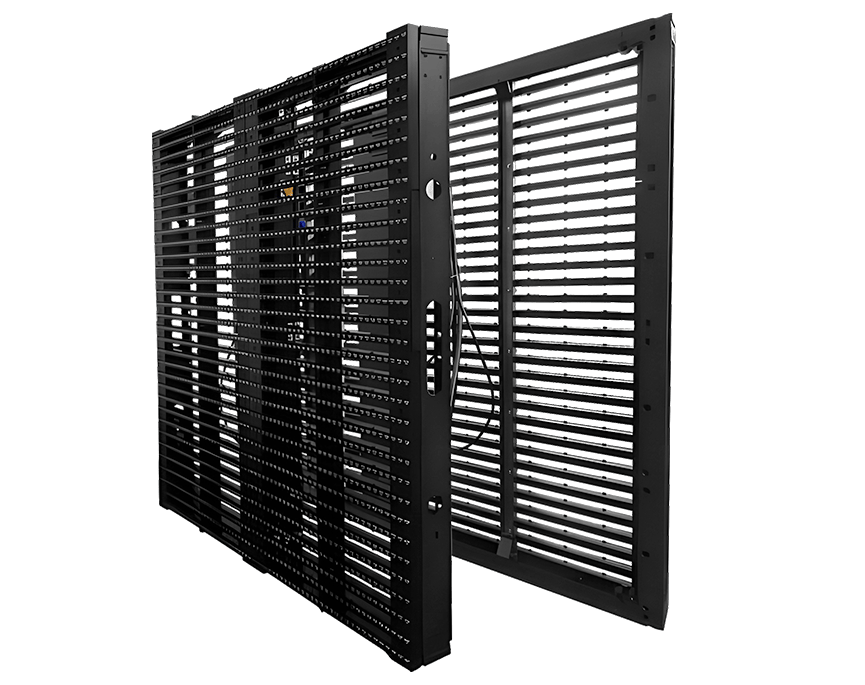

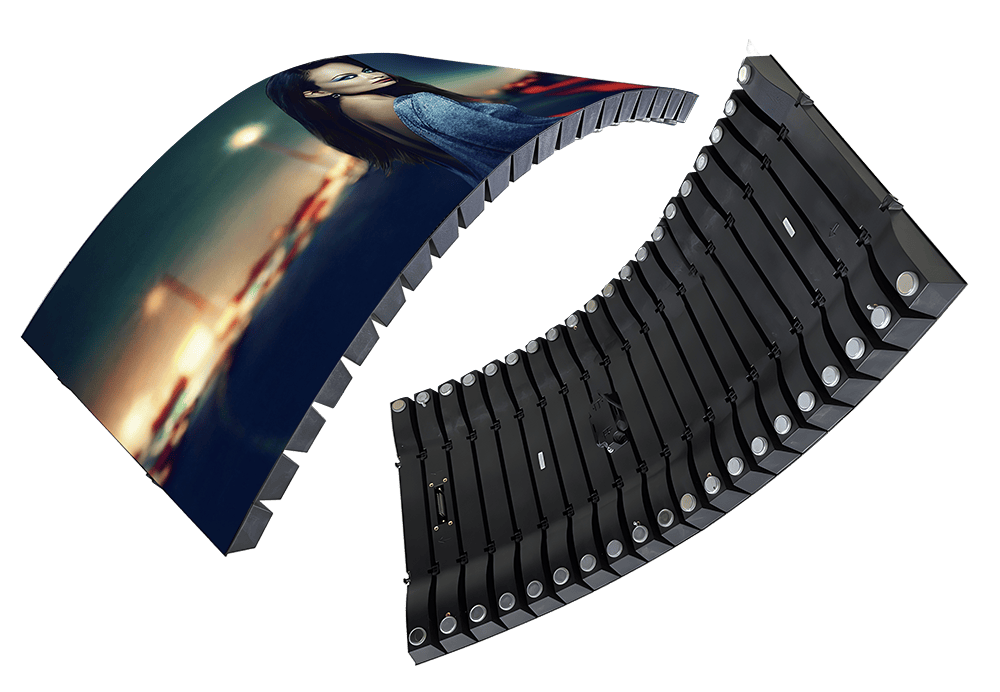

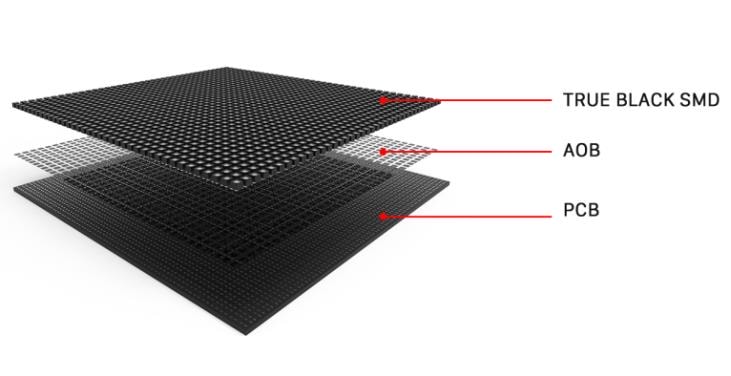

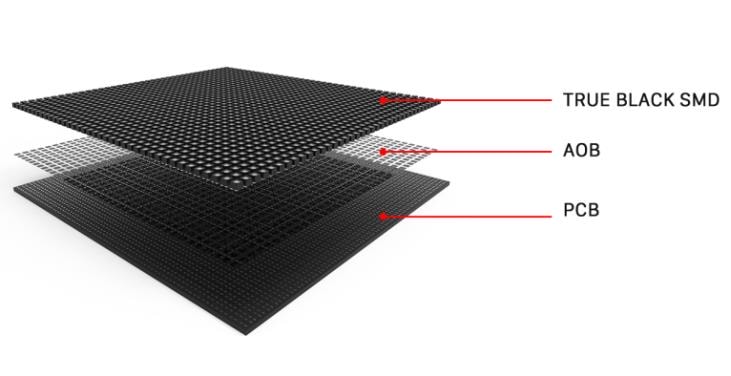

In order to give the LED better protection, there are two solutions: AOB and GOB.

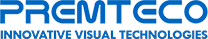

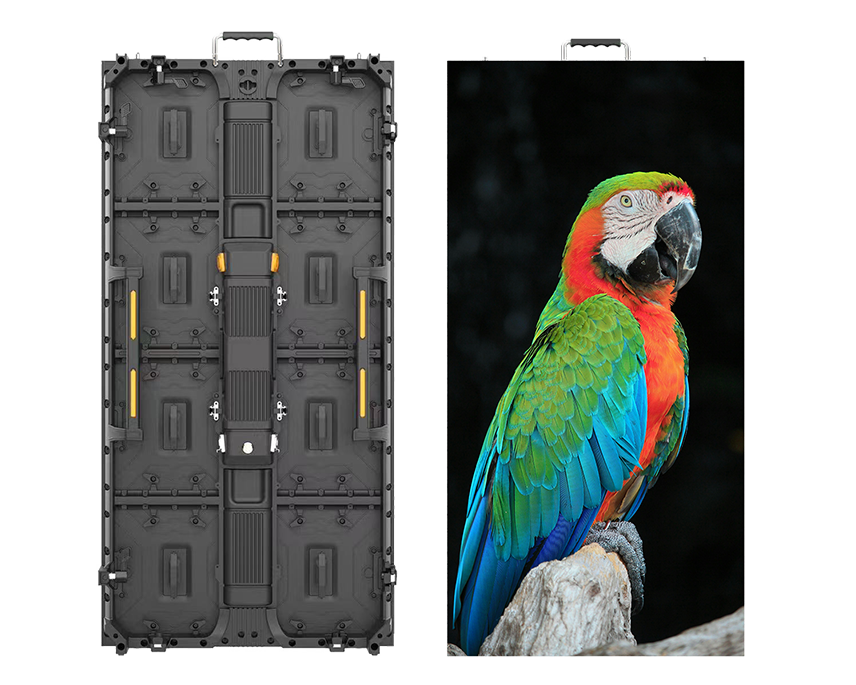

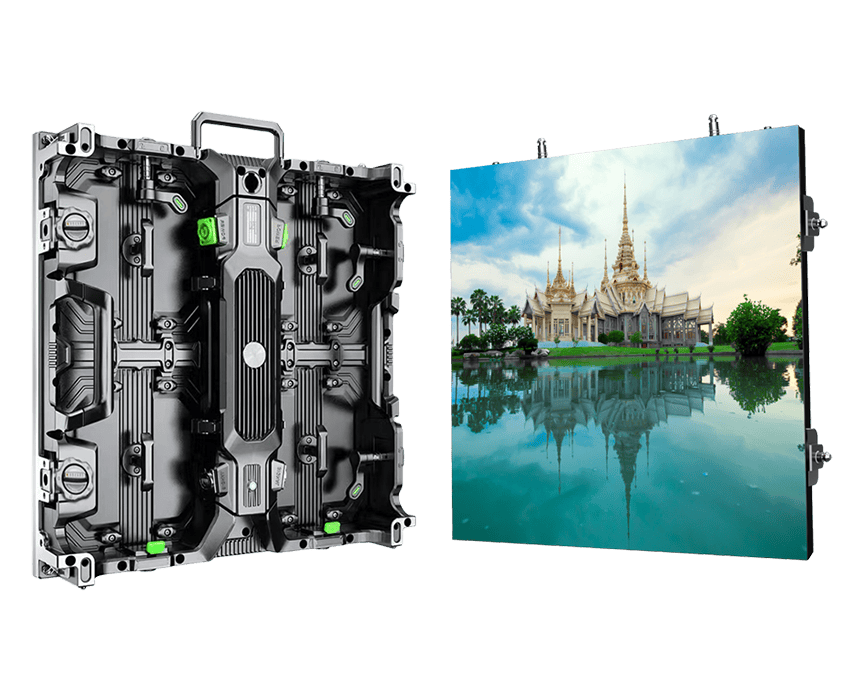

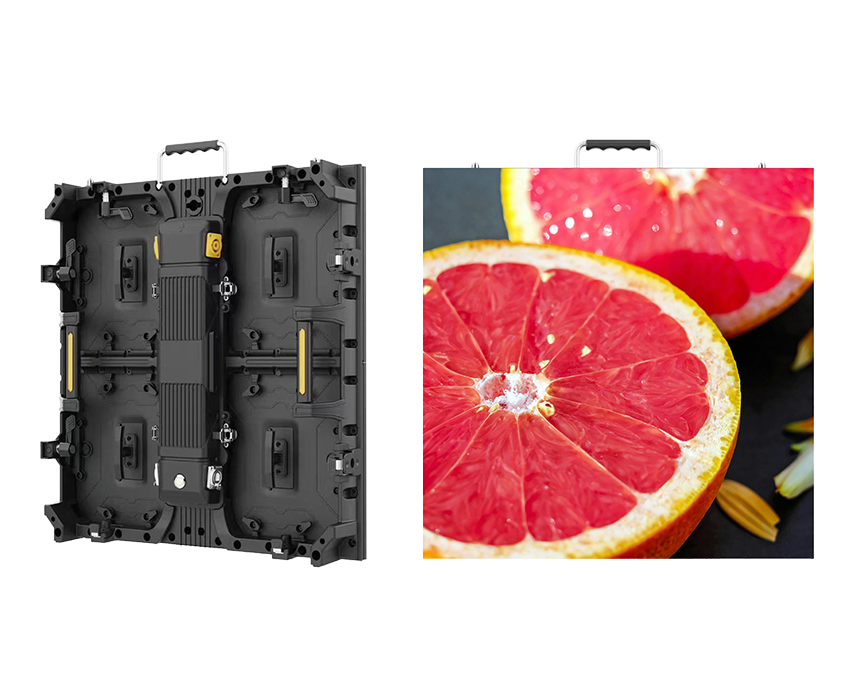

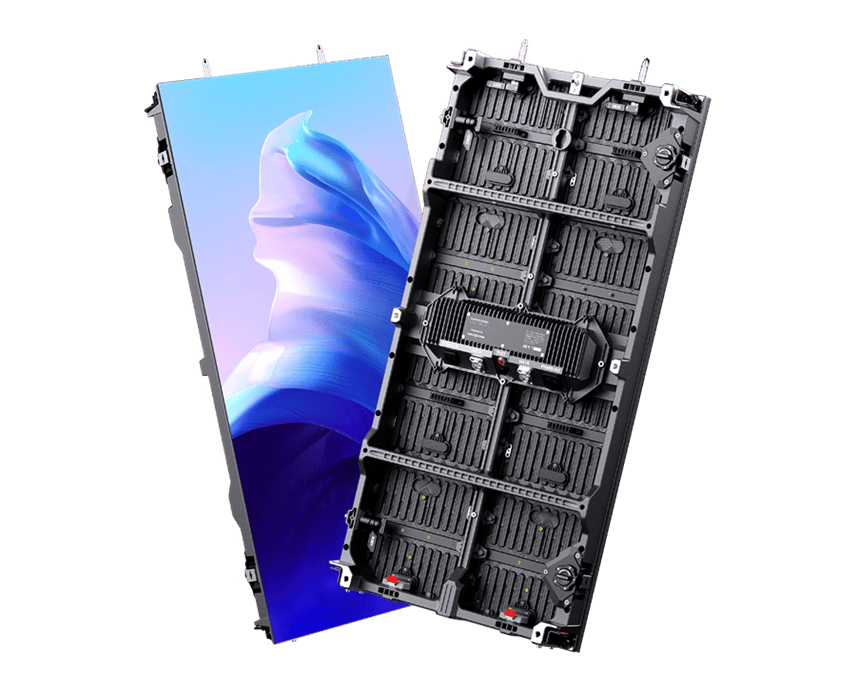

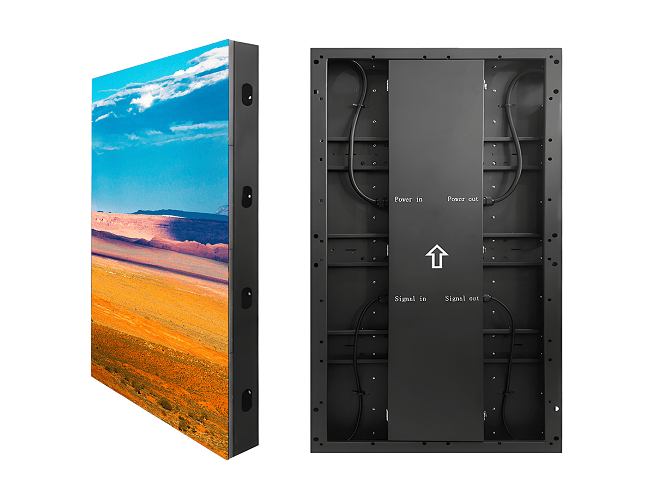

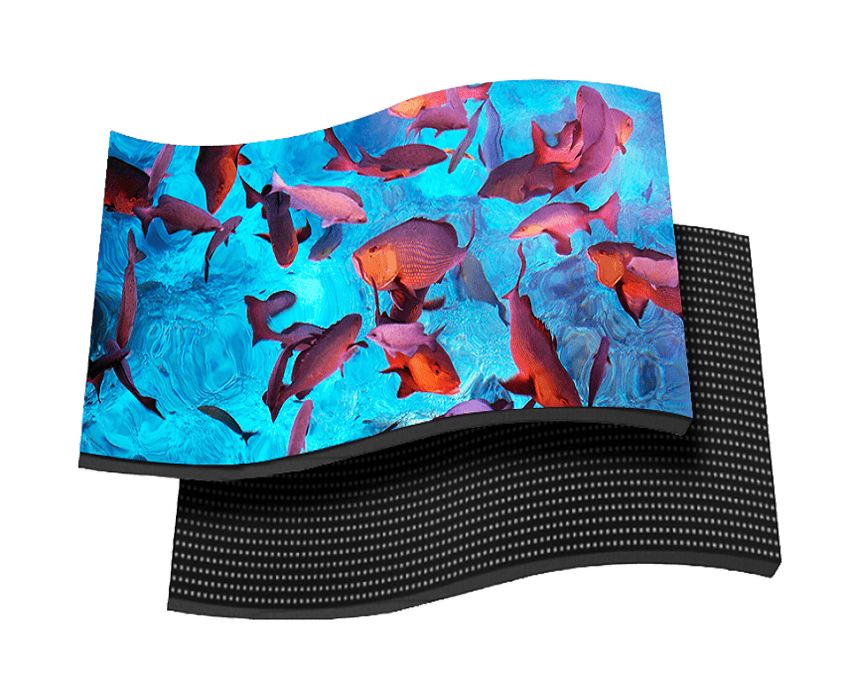

AOB means adhesive on board. We put the adhesive on the LED’s leg, so that soldering connection between LED and PCB board will be reinforced. Because the adhesive is only used on the leg of the LED, so the appearance of the LED which is adopted the AOB look almost same as the regular LED module.

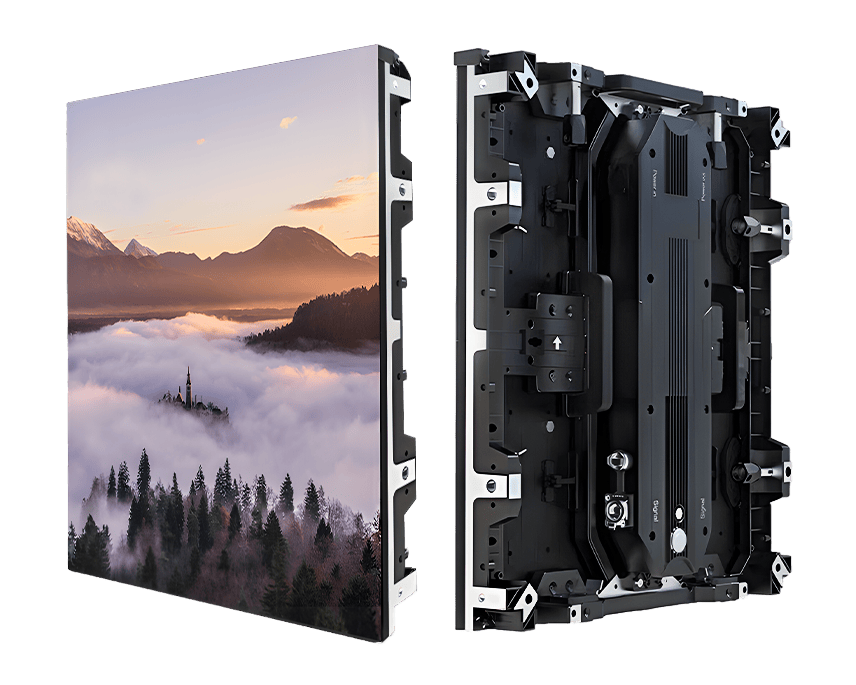

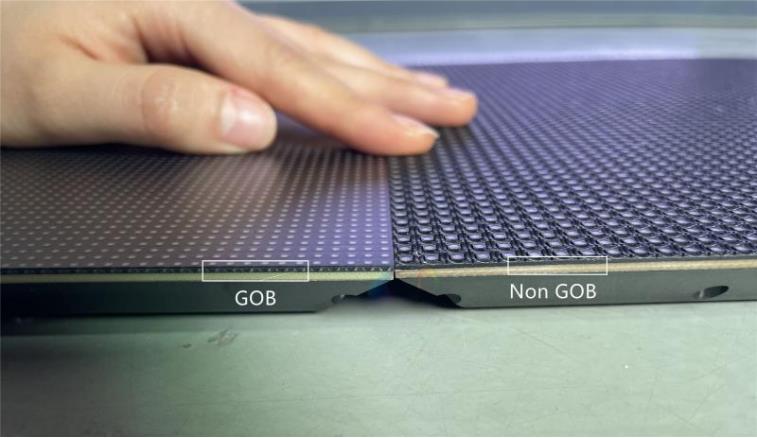

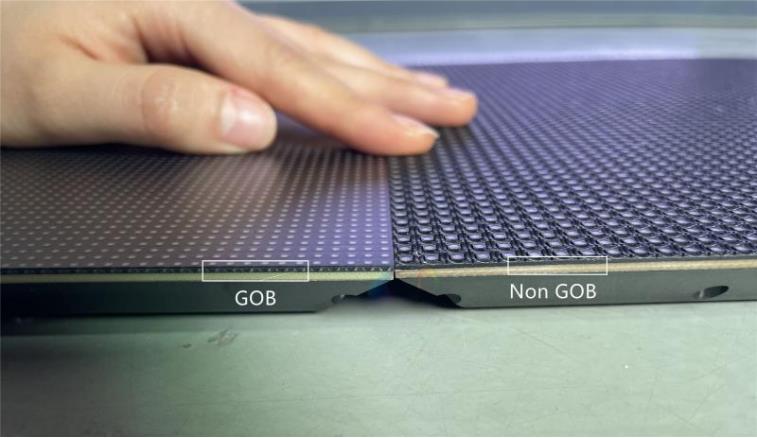

GOB means glue on board. There will be a clear glue on the top the module. Please view the attached photos. As the LED is covered by the glues, so the LED has much better protection.

The comparison between GOB and AOB:

1)GOB has much higher cost than AOB.

2)Protection: GOB has better protection than AOB. Since LED will be fully covered by the glue if we use GOB, so the protection of the GOB is much better. For AOB, it offers less protection than GOB does, but it still can protect the LED in some degree. Although the LED module has the protection from AOB, we still need to handle the LED module carefully during the installation.

3) Visual effect and reliability. AOB has better visual effect in a long run. When we use GOB, since the LED is fully covered by the glue, the heat dissipation will be affected, so the LED’s lifespan will be shortened after few years. Meanwhile, although the glue is crystal cl ear at the beginning, the glue’s appearance will turn white after few years, and the white balance of the screen will get worse. AOB doesn’t have this kind of issue since the adhesive is only on the LED’s leg.

For P1.9 and smaller pixels we recomend GOB, while for P2.5 and bigger pixels we recomend AOB. Also you can choose the one you want for your project. PREMTECO offers best advanced technology for your screens.