Common Cathode vs. Common Anode: A Detailed Comparison

Views: 159936

Author: Site Editor

Publish Time: 2024-06-29

Origin: Site

In the early stage, LED displays were mostly used for outdoor applications with larger pitch products. Since they were designed as static scanning drives, there was no physical space limitation for the driver IC. However, when LED displays start to be used in indoor applications and products with smaller pitches are used, the space available for electronic components is squeezed. Therefore, dynamic scan drive (line-scanning drive) based on time division multiplexing (TDM) appears . In the line scan driving mode, the LED display can be divided into two types: common cathode and common anode.

What is Common Cathode

Common Cathode is a configuration used in LED displays and other semiconductor devices, where the cathode (negative terminal) of each LED is connected to a common ground or common negative terminal. This setup is particularly common in multi-segment displays, such as seven-segment displays or RGB LEDs.

How Common Cathode Configuration Works

A common cathode configuration connects the cathodes (negative terminals) of multiple LEDs to a common ground, simplifying the circuit design. Each LED's anode (positive terminal) is connected to an individual control line. To illuminate an LED, a positive voltage is applied to its anode, allowing current to flow from the anode to the cathode, thus lighting the LED. This setup is efficient for controlling LEDs with a common ground reference, making it ideal for applications like seven-segment displays and RGB LEDs where individual LED control is required.

Advantages of Common Cathode Configuration

The common cathode configuration offers several benefits that make it a popular choice in various electronic applications. These advantages include simplified ground management, ease of control, and potential power efficiency. Here’s a closer look at each benefit:

-

Simpler Ground Management: Since all cathodes are connected to a common ground, it simplifies the design of the circuit, especially when interfacing with microcontrollers and other digital logic circuits that typically use a common ground reference.

-

Ease of Control: Easier to manage in circuits where controlling the positive voltage to individual LEDs is more straightforward.

-

Potential Power Efficiency: May offer better power efficiency in certain applications because of reduced voltage drops across the common ground.

What is Common Anode

Common Anode is a configuration used in LED displays and other semiconductor devices, where the anode (positive terminal) of each LED is connected to a common positive voltage. This setup is particularly common in multi-segment displays, such as seven-segment displays or RGB LEDs.

How Common Anode Configuration Works

In a common anode configuration, the anodes (positive terminals) of multiple LEDs are connected to a common positive voltage source. Each LED's cathode (negative terminal) is connected to an individual control line. To illuminate an LED, a negative voltage is applied to its cathode, allowing current to flow from the common anode to the cathode, thus lighting the LED. This setup is ideal for circuits using a common positive voltage and allows individual control of each LED.

Advantages of Common Anode Configuration

The common anode configuration offers several distinct advantages that make it a preferred choice in many electronic applications. These benefits include compatibility with positive logic systems, simplified power supply design, and flexibility in design. Here’s a closer look at each advantage:

-

Compatibility with Positive Logic Systems: This configuration is often easier to interface with control systems that use positive logic, where the common anode can be connected directly to the positive supply voltage.

-

Simplified Power Supply Design: The common anode configuration can simplify the design of the power supply and control circuitry in systems that utilize a common positive voltage.

-

Flexibility in Design: Common anode configurations can be more flexible for certain applications, especially those involving multiple LEDs in series or complex display matrices.

Common Cathode vs. Common Anode

| Feature |

Common Cathode |

Common Anode |

|

Connection

|

All cathodes connected to a common ground

|

All anodes connected to a common positive voltage

|

|

Control Method

|

Individual anodes controlled with positive voltage

|

Individual cathodes controlled with negative voltage

|

|

Compatibility

|

Easier with ground-referenced control circuits

|

Easier with positive logic control systems

|

|

Power Supply Design

|

May be more efficient due to reduced voltage drops

|

Simplifies design in systems with common positive voltage

|

|

Typical Applications

|

Seven-segment displays, RGB LEDs

|

Seven-segment displays, RGB LEDs

|

|

Driving Logic

|

Positive voltage turns on the LEDs

|

Negative voltage turns on the LEDs

|

|

Common Use Cases

|

Digital clocks, calculators, multi-segment displays

|

Digital clocks, calculators, multi-segment displays

|

Key Differences Between Common Cathode and Common Anode

Connection

In common cathode configurations, all cathodes are connected to a common ground, while each anode is individually controlled with a positive voltage. Conversely, in common anode configurations, all anodes are connected to a common positive voltage, and each cathode is individually controlled with a negative voltage. This distinction impacts how the LEDs are driven and integrated into circuits.

Control Logic

Common cathode configurations are easier to control with circuits that have a common ground, making them ideal for systems that use ground-referenced logic. On the other hand, common anode configurations are suitable for circuits with a common positive voltage, aligning well with positive logic systems. This difference determines the ease of integration based on the control logic of the circuit.

Powering LEDs

In a common cathode configuration, LEDs are turned on by applying a positive voltage to their anodes, allowing current to flow through to the common ground. Conversely, in a common anode configuration, LEDs are activated by applying a negative voltage to their cathodes, with current flowing from the common positive voltage. This difference in voltage application affects how the LEDs are powered and controlled in various circuit designs.

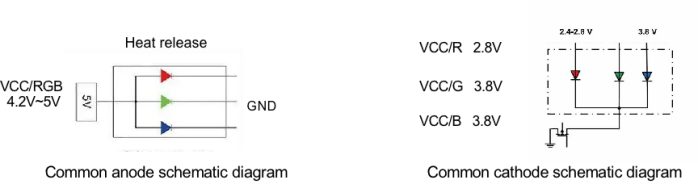

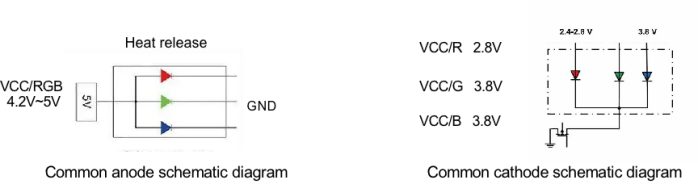

Current Direction

In common anode mode, the current of the LED display flows from the PCB to the LED diode, and the RGB LEDs are powered by the same power supply at the same power rate, so the forward voltage drop will increase. In the common cathode mode, the current of the LED display first flows through the LED diode, the R, G and B LEDs are powered separately, and then to the negative pole of the integrated circuit. The forward voltage drop is reduced and the internal conduction resistance is reduced.

The Supply Voltage

In the common anode mode, the LED display provides a unified voltage higher than 3.8V (such as 5V) for the RGB LEDs, so it consumes a lot of power. In common cathode mode, the LED display provides separate voltages for R, G, B LEDs (2.8V for red LEDs, 3.8V for green and blue LEDs) according to actual needs. Power efficiency is higher due to this independent and precise power supply. Therefore, as less electricity is consumed, less heat is generated.

Applications

Both common cathode and common anode configurations are widely used in seven-segment displays, RGB LEDs, and other multi-segment displays. The choice between them depends on the design of the control circuitry, with common cathode suited for ground-referenced logic and common anode for positive logic systems.

Conclusion

Understanding the differences between common cathode and common anode configurations is crucial for designing and implementing LED displays effectively. Each configuration offers unique advantages depending on the control logic and power supply design of your project. Whether you need ground-referenced control for common cathode setups or positive voltage systems for common anode configurations, choosing the right configuration can enhance the performance and efficiency of your LED displays.

For high-quality LED display solutions, PTcled is a reliable manufacturer, offering a range of products tailored to meet your specific needs. With our expertise and commitment to excellence, you can trust PTcled to provide top-tier LED displays for any application.