How does the LED display respond to the challenge of low temperature environment?

Views: 3618

Author: Site Editor

Publish Time: 2022-02-18

Origin: Site

In some countries and regions around the world, most of the temperature is below -30℃ throughout the year, and even in some areas, the temperature is even lower. For example, in some European countries such as Russia, the historical minimum temperature is -71℃; the extreme minimum temperature in North America is -63℃; In northern my country, Harbin, Changchun, and Hohhot are the TOP3 coldest cities in the country, and the weather station recorded an extreme low temperature of -58°C. Therefore, LED displays in low temperature areas face great challenges.

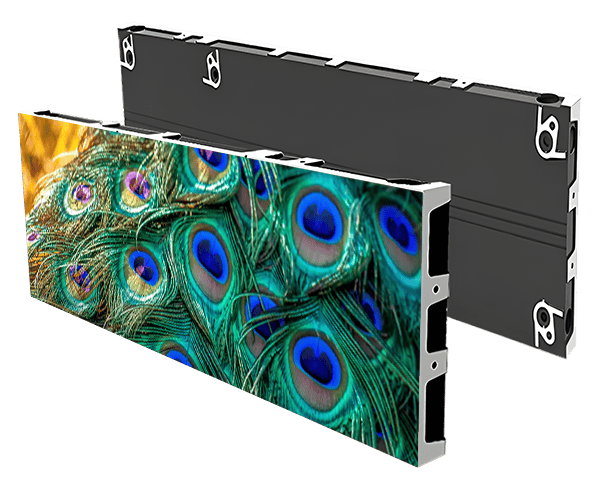

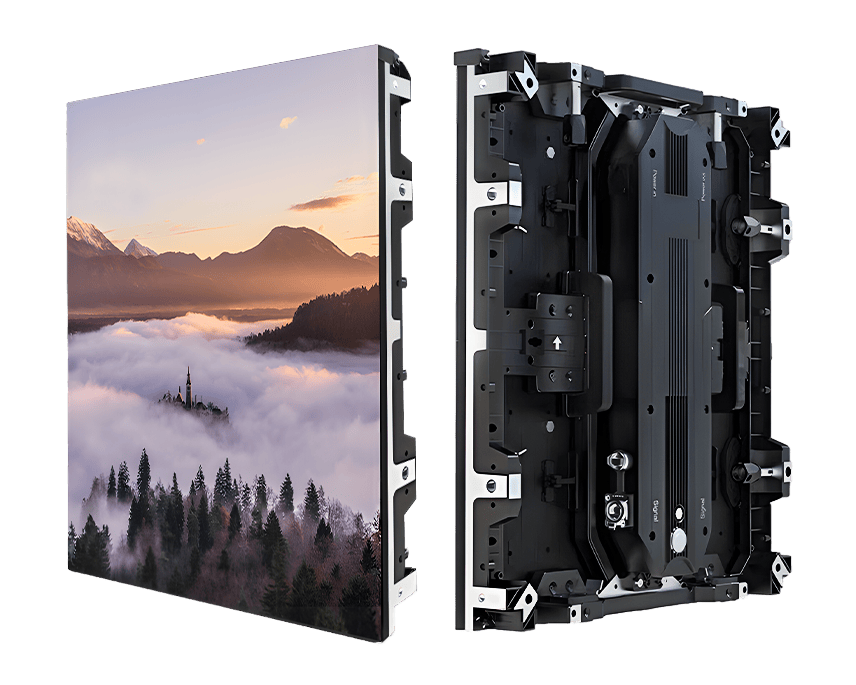

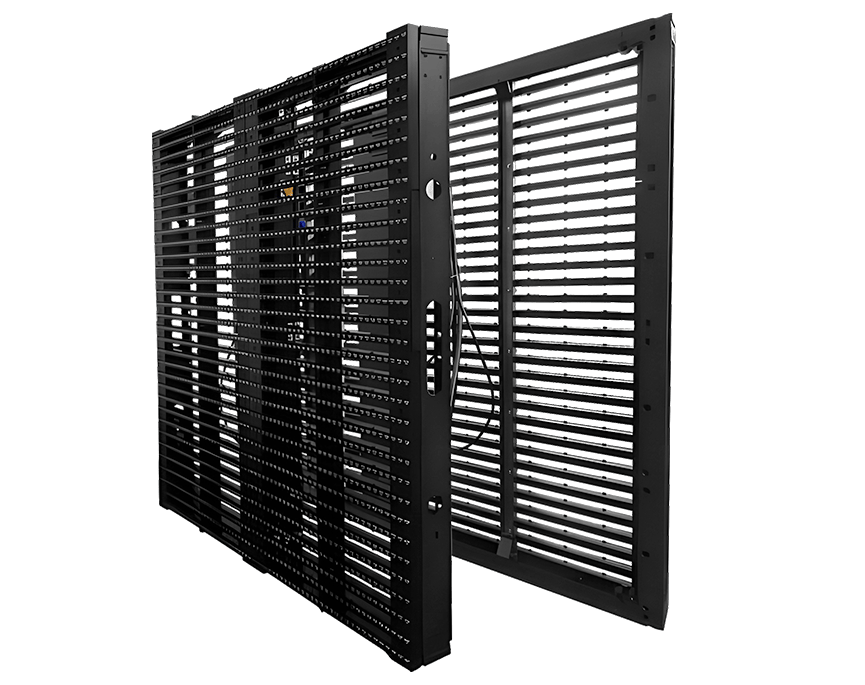

For LED displays installed outdoors, in a low temperature environment, the various materials that make up the LED display, such as masks, PCBs, module kits, box frames, etc., have different thermal expansion and contraction coefficients and inconsistent changes in physical dimensions. , Easy to appear:

1. There is a gap between the module and the module, the box and the box;

2. The package shrinks and breaks caused by the inconsistent shrinkage of the module kit and the box frame;

3. The lamp beads attached to the PCB are inconsistent with the shrinkage of the mask, causing the lamp beads to loosen and display failure;

4. The hidden dangers of water ingress caused by low-temperature shrinkage, such as the waterproof rubber ring of the cabinet;

5. The electronic device cannot start and work normally.

In addition, in a low temperature environment, the protective layer attached to the surface of the wire is easily damaged, causing serious problems such as short circuits or even fire; outdoor LED displays may also have some electronic components that cannot work properly, making the entire screen unable to work properly.

In response to the above problems, outdoor fixed LED displays can deal with low-temperature environments through the following solutions.

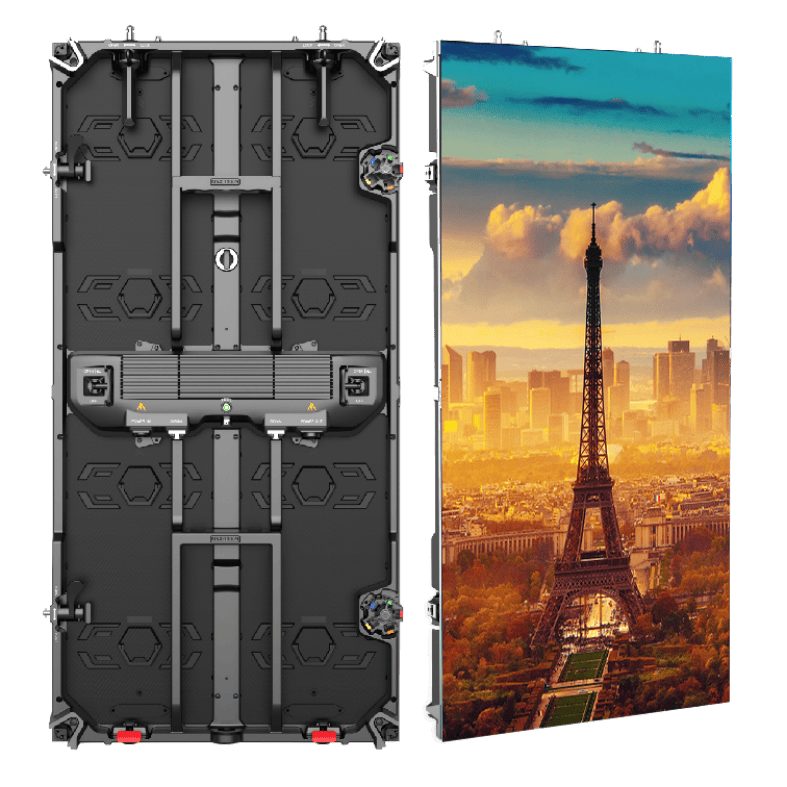

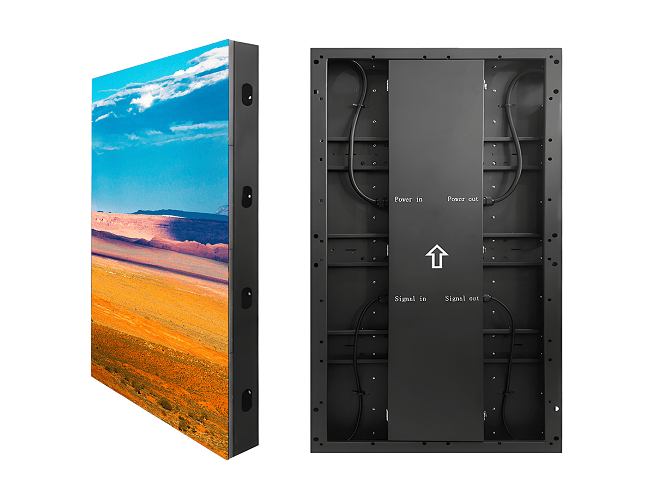

Selection of low temperature resistant raw materials

Objects tend to become brittle at low temperatures, and LED display products also face such risks. Use low-temperature resistant raw materials and components, such as cold-resistant masks and bottom shell kits, low-temperature resistant waterproof glue, low-temperature power supply (can be started in an environment of -40℃; -25℃); use low-temperature resistant cabinets, low-temperature resistant electronic devices and Connectors.

Exquisite craftsmanship, super high protection ability

Since outdoor fixed LED screens work in an outdoor environment for a long time, the PCB, power supply, solder joints, etc. have high requirements for high and low temperature resistance, water resistance, and corrosion resistance. It is recommended to carry out conformal coating and cold-proof treatment for PCB, components and parts, solder joints, etc., such as containing chemical substances (for example: fuel, coolant, etc.), vibration, humidity, salt spray, humidity and high temperature, low temperature conditions Protect circuits from damage, thereby prolonging their service life.

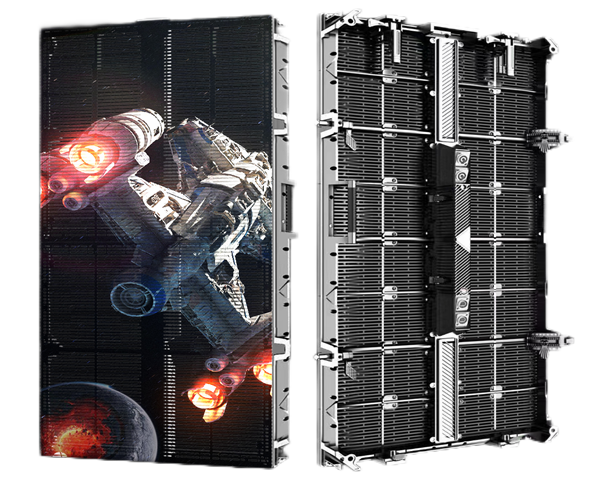

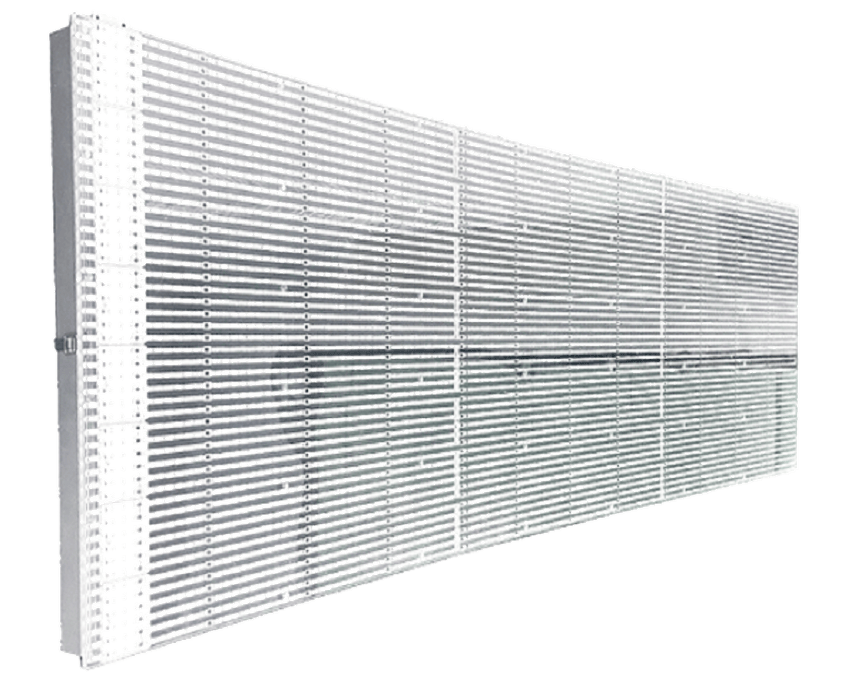

Install a hot air curtain inside the screen

Make a closed channel inside the large screen, and install a hot air axial flow at the rear, and its working state will be realized by the temperature control system. When the temperature is lower than the minimum ambient temperature for power startup, the air curtain will heat up, and the screen can be turned on normally after the temperature of the screen rises. When the temperature reaches the set temperature, the temperature control system will cut off the power supply.