SMD LED Vs DIP LED Vs COB LED, Which Is Better?

Views: 8902

Author: Site Editor

Publish Time: 2025-07-29

Origin: Site

Today we will compare three different concepts, SMD LED, DIP LED and COB LED. Hope this article can help you have a better understanding of these three concepts.

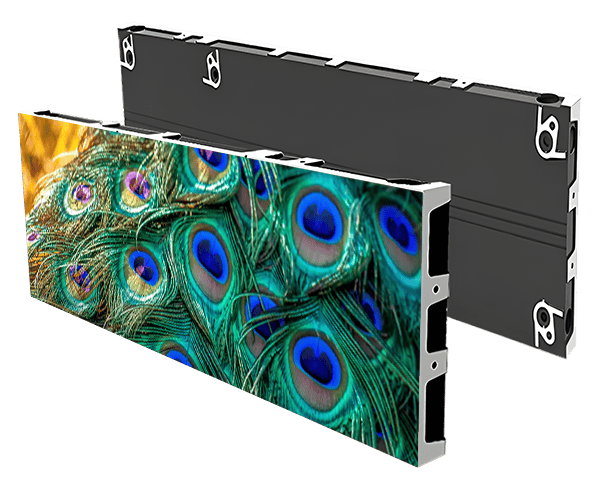

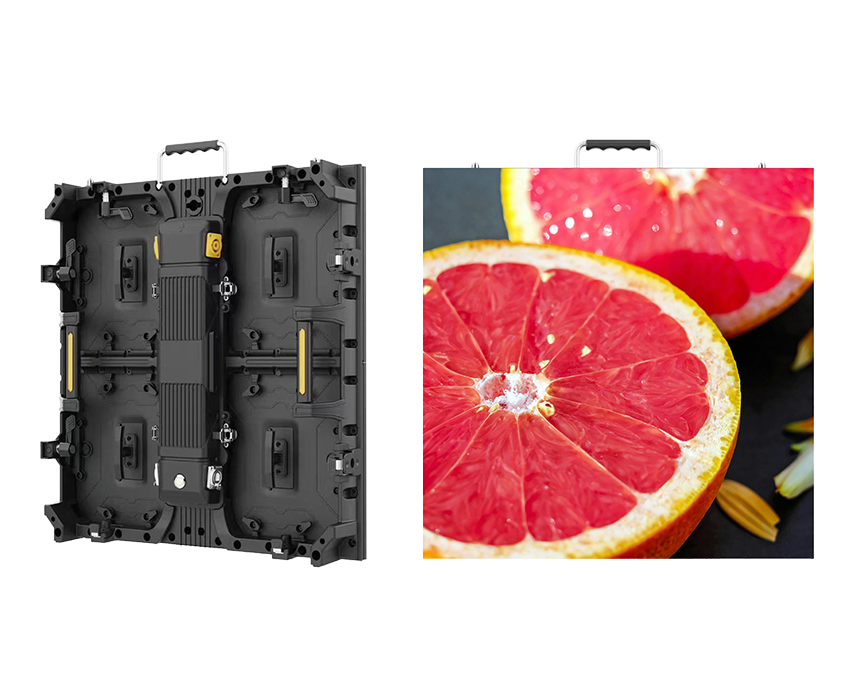

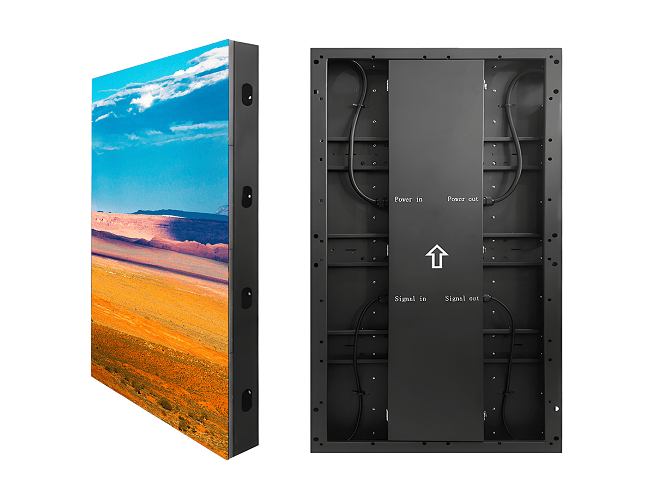

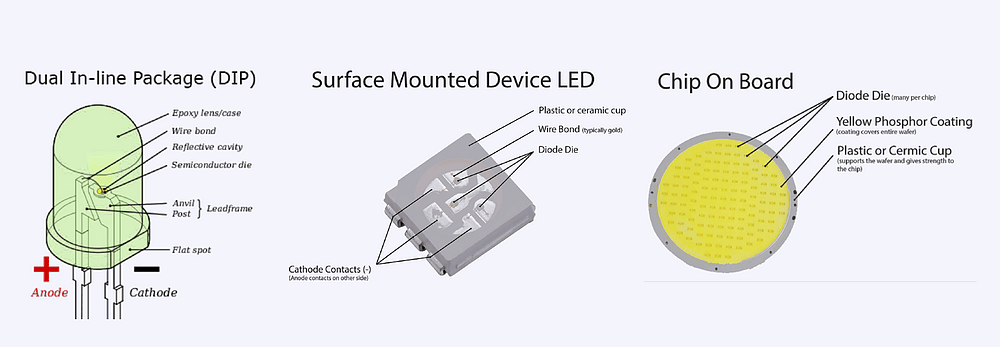

DIP LED

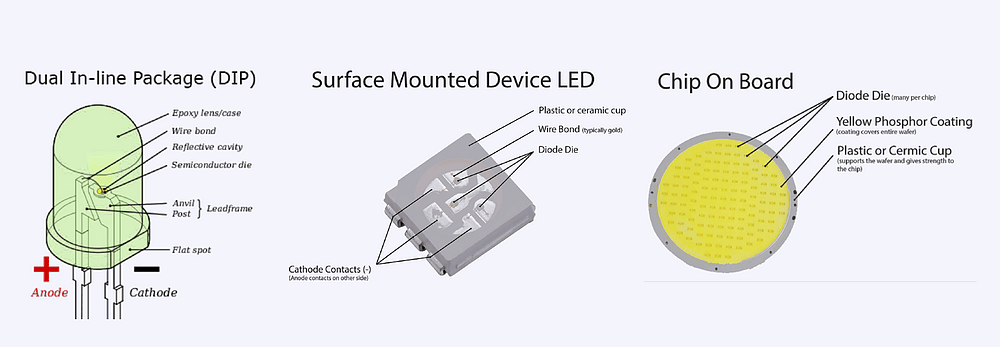

DIP is the abbreviation of dual inline-pin package, a plug-in package. The display manufacturer inserts the LED beads into the LED PCB board, and produces DIP semi-outdoor modules and outdoor waterproof modules through wave soldering.

Due to the impact of the LED bead diameter, the current DIP outdoor pixel pitch can only be as low as P10, which cannot meet the market demand for higher-density outdoor display screens. However, DIP packaging is more protective, and as the first technology developed among the three packaging modes, the current production technology is very mature and it can reach higher brightness than SMD Led, and is suitable for outdoor large pitch displays.

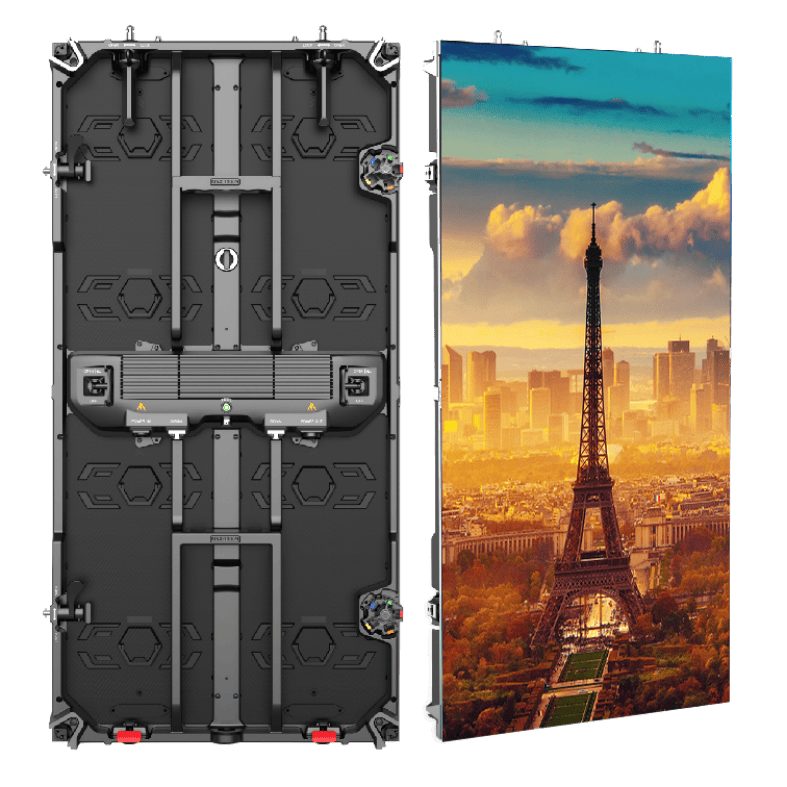

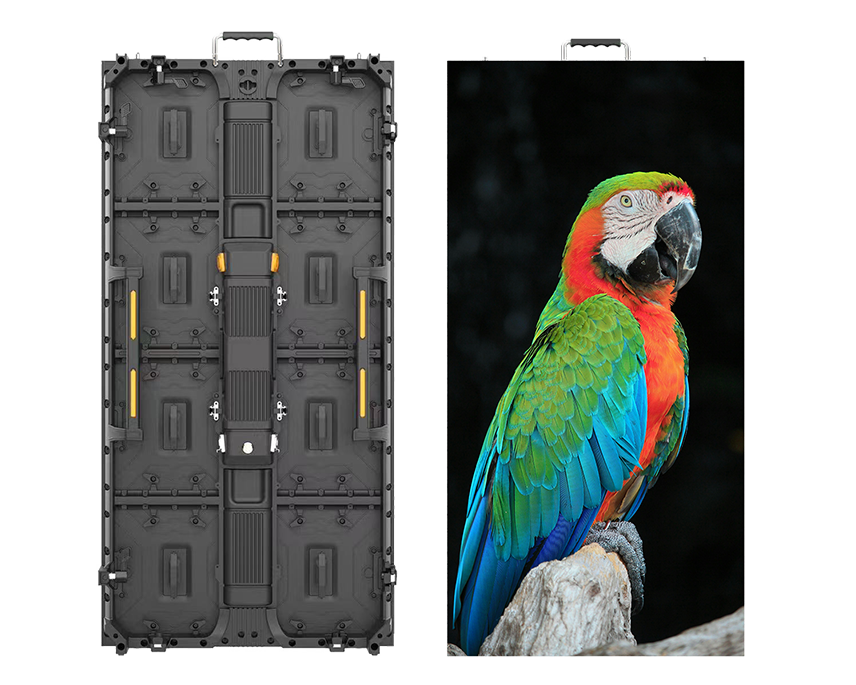

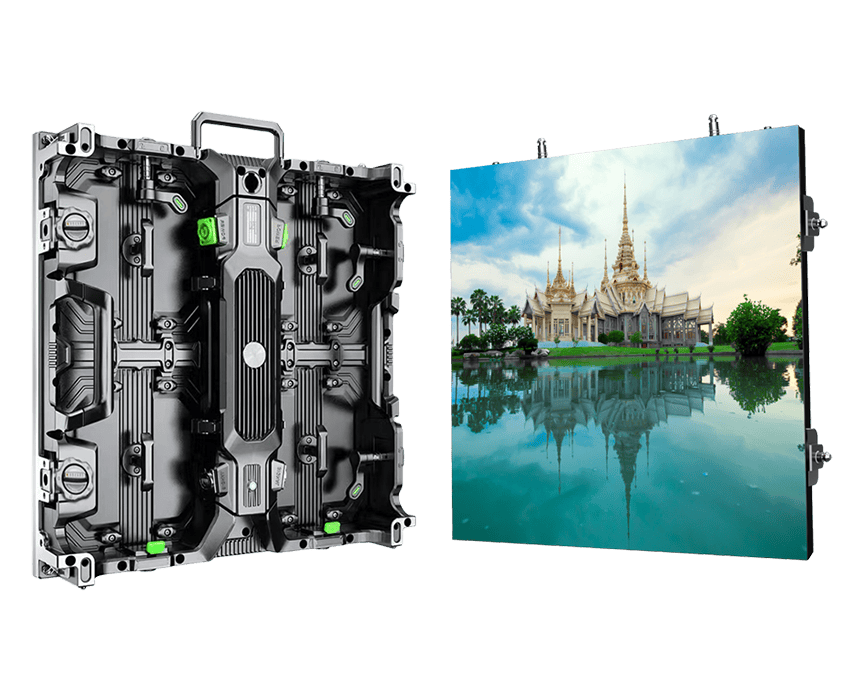

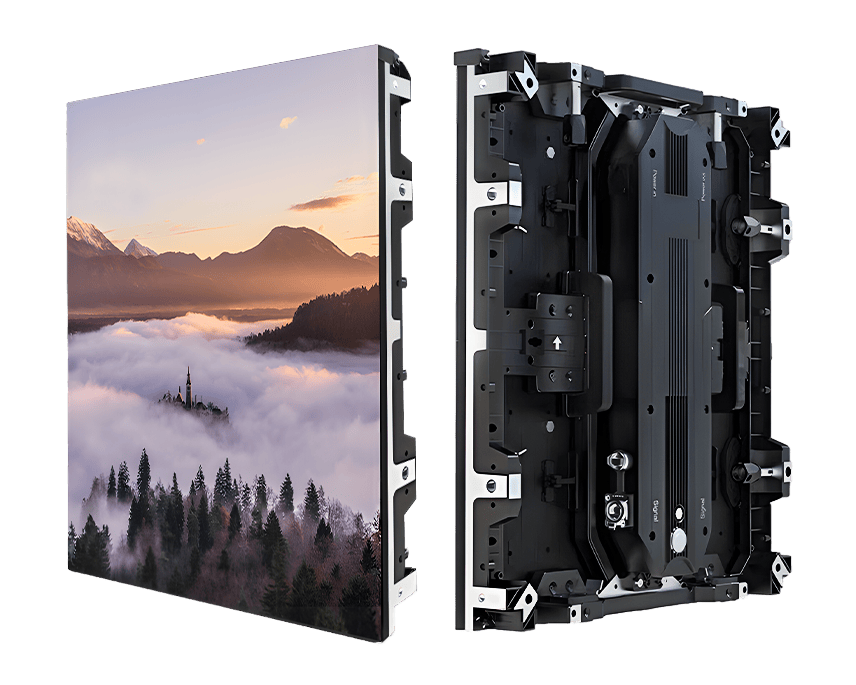

SMD LED

SMD is the abbreviation of Surface Mounted Devices, which means surface mount device. It is one of SMT (Surface Mount Technology) components.

The viewing angle of the full-color LED display with SMD technology is larger than that of DIP, and the surface can do light diffuse reflection processing. The resulting effect is not granular, the color uniformity is good and wide pixel choice offers are available. At present, because of the madure industrial technology, great visual effect and economical price, SMD is the default first choice for indoor and outdoor LED displays.

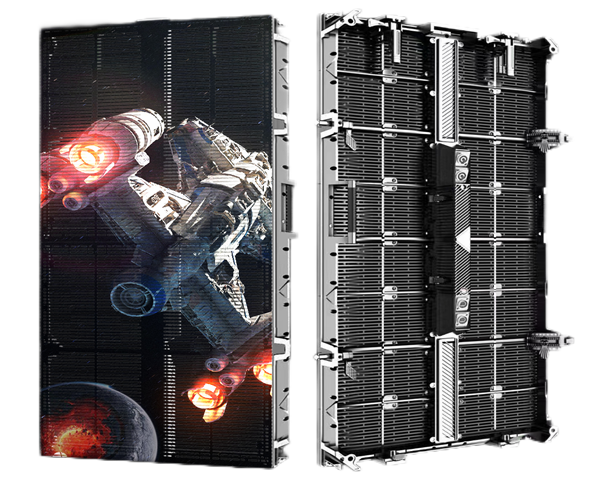

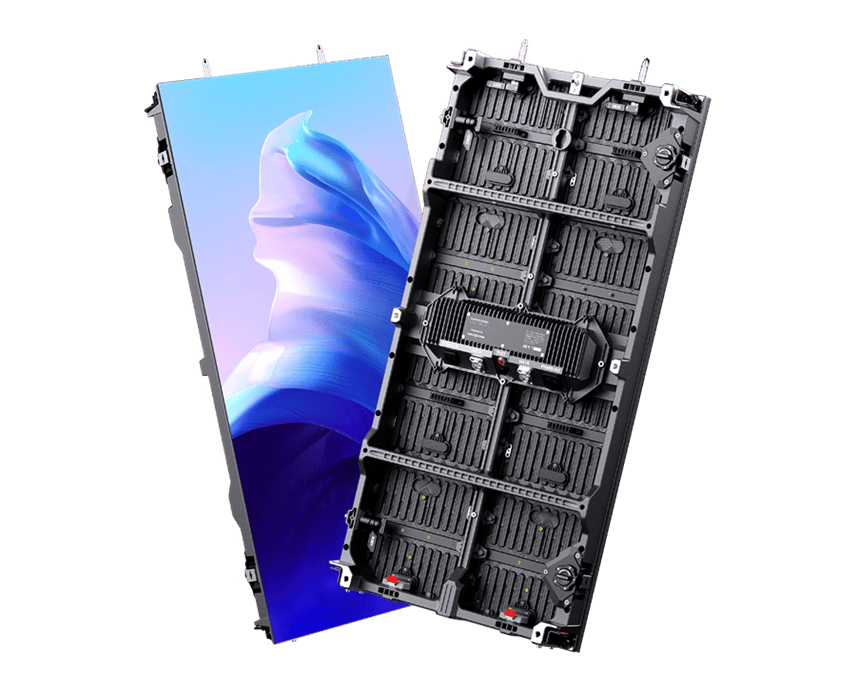

COB LED

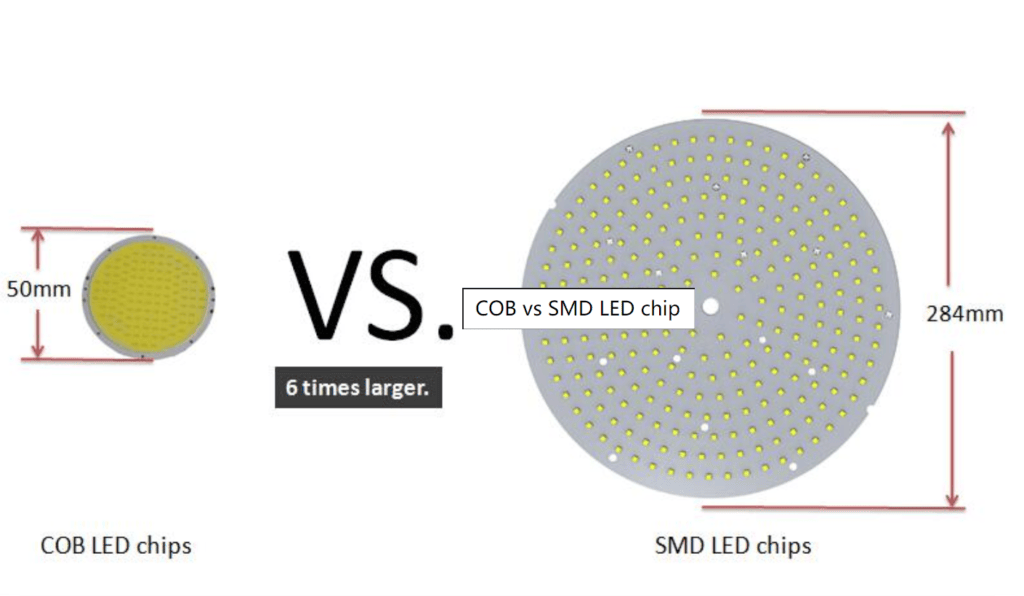

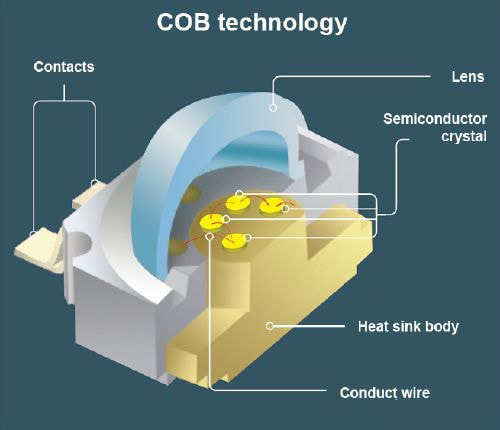

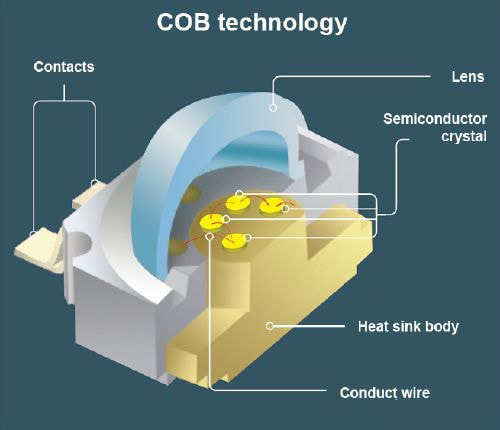

COB is the abbreviation of Chip On Board, which means chip-on-board packaging technology. It is a semiconductor packaging process in which the chip is bonded to an interconnect substrate with conductive or non-conductive adhesive, and then electrically connected by wire bonding.

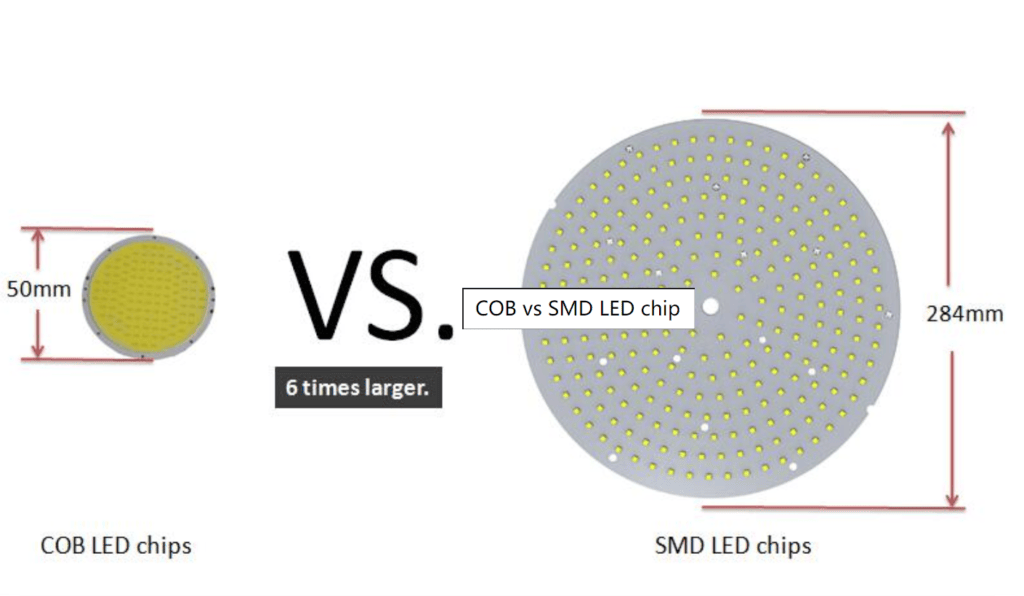

As a new type of packaging method, COB has obvious advantages. It can achieve P0.9 or even smaller dot pitch, which meets the market's demand for more high-definition displays. The LED display of this packaging technology is also lighter and thinner, with higher surface flatness. However, the current cost of COB production is relatively high, and cannot be applied to outdoor LED display products.

The development of these three technologies, DIP, SMD, and COB, has evolved with the development of technology and market demand. They are an upgrade process rather than a complete replacement process. Therefore, there is no absolute better or worse difference between these three packaging methods. The best option is to choose an LED display with a suitable packaging method according to the needs of the specific project.

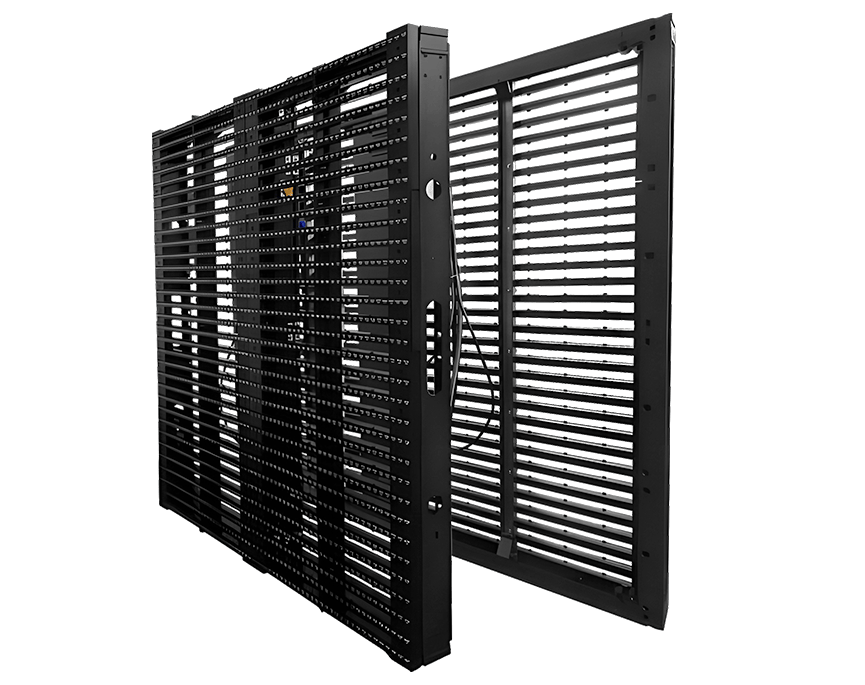

PTCLED has built up an outstanding reputation in the industry by supplying consistent and reliable LED display products, which allow you to build a strong brand image, and catch the attention of new potential customers or enhance the visual performance of your stage. Meanwhile, we keep updating advanced facilities and automatic machines. In addition, we are fiercely committed to providing exceptional service to our customers. If you have any need for an LED display, kindly contact us.