The characteristics of AOB and what are its advantages.

Views: 3902

Author: Site Editor

Publish Time: 2021-10-27

Origin: Site

As we all know, SMT surface mount technology has mature technology and is currently the mainstream technology in the LED display market. SMD surface mount display market accounts for up to 95%. However, as its application becomes wider and more popular, in some special application environments, the surface mount display often shows that the lamp bead is not bright, the column is bright, the lamp is dead, the lamp is off, afraid of cold wind, water vapor, dust, and scratches. Rubbing, bumping, bumping, etc. are mostly problems. Therefore, how to improve the protection level of the light board, reduce the dead light rate, and improve the display effect has become the focus of many industrial enterprises.

This essentially solves the impact of the SMD surface mount screen during installation and use, the damage caused by scratching and the scrap of the light board, as well as the erosion of the LED lamp beads caused by the air-conditioning cold wind-water vapor, splashing water, etc. during long-term use. The defects of the lamp beads in the use process improve the safety of installation and maintenance, especially in the rapid response of major meetings and the key pictures will not appear lack of color or light on the lamp beads. The overall defect of the lamp beads is reduced to 5PPM the following.

Where is AOB sacred? How to add surface stickers to display new skills?

AOB (Admixture On Board) is the last process arranged in the production of surface mount LED displays. After the SMT process is completed, a layer of polymer material film is coated on the surface of the light board. Previously, the display has passed the 72H constant temperature aging of the lamp panel white balance and 24H video aging of the entire screen, eliminating all kinds of defects caused by the production process and components, and the isolation protection of AOB nano-coating will reduce the LED failure rate to 5PPM The following greatly improves the yield and reliability of the screen.

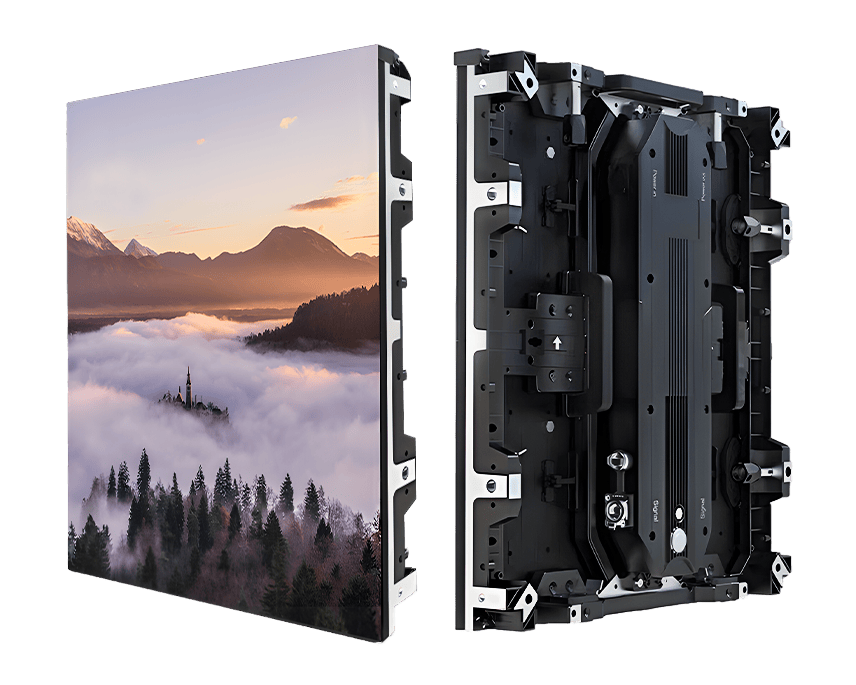

The side anatomical diagram of the AOB program is as follows:

Three characteristics of AOB:

1) Physical protection characteristics

The physical protection of AOB is achieved by the bottom layer of filler. This type of gel has bonding properties similar to solder paste, but it is also an insulating material. This type of filler wraps the bottom of the LED as a whole, which increases the size of the LED and the bottom. The contact ability of PCB, through laboratory tests, conventional SMT soldering side push strength is 1kg, AOB product side push strength is 6kg, this can solve the problem of bumps during the installation process, and even the lamp board cannot be repaired due to the falling off of the pad.

2) Chemical protection properties

The chemical protection characteristic of AOB refers to the matte transparent protective layer wrapped around the LED. This layer is made of polymer material through nano-level coating technology to completely seal the LED in this protective layer, blocking the contact with the outside. In this way, water vapor will not enter the inside of the particles, and the lamp beads will not be affected by the environment during use.

At the same time, the hardness of this layer of material is HRC8 hardness, so that easy scratching will not form marks on the surface of the screen.

3) New discoveries under protective features

Increased viewing angle: The matte transparent protective layer is equivalent to adding a lens to the front of the LED, which increases the light-emitting angle of the LED lamp beads. After testing, the light-emitting angle of the lamp beads can be increased from 140° to 170°.

Light mixing characteristics: SMD surface mount devices emit light from a point light source. Compared with the surface light source, the graininess is more obvious. AOB is equivalent to adding a piece of transparent glass to the SMD LED. After reflection and refraction, the light graininess is much reduced. It can reduce the moiré effect and enhance the light mixing characteristics.

Black screen consistency: PCB ink color inconsistency has been a problem that has plagued SMD displays for many years. Just like the surface consistency of COB, it cannot be solved. Unless one batch is produced, although the mask can solve the problem of inconsistent ink color of SMD display PCB light board, what brings is the reduction of the viewing angle, the side view is unacceptable, and the mask is uncontrollable. AOB achieves the coating thickness and color control, which effectively solves the problem of PCB ink color inconsistency, and does not lose the viewing angle, which can be perfect Solve the problem of the common use of different batches of PCB light boards and improve shipping efficiency.

Contrast increase: Nano-level coating can achieve fine control, and the material composition can be controlled, which can increase the blackness of the screen background and increase the contrast.

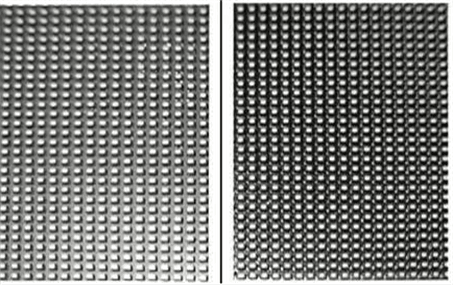

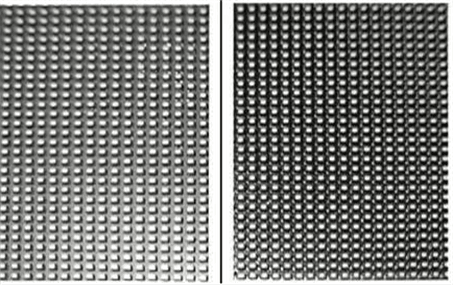

AOB package appearance comparison (left) without AOB (right) with AOB, patent mark

The AOB process based on the SMD LED display makes up for the shortcomings of SMD in terms of protection performance without affecting the original supply chain ecology and cost performance, thereby contributing to its display effect and maintenance convenience advantages. fully use. The advent of AOB undoubtedly provides a more high-quality choice for indoor display solutions, and will become a highlight in the evolution of LED display technology.