What are COB and GOB LED Display?

Views: 7326

Author: Site Editor

Publish Time: 2021-11-23

Origin: Site

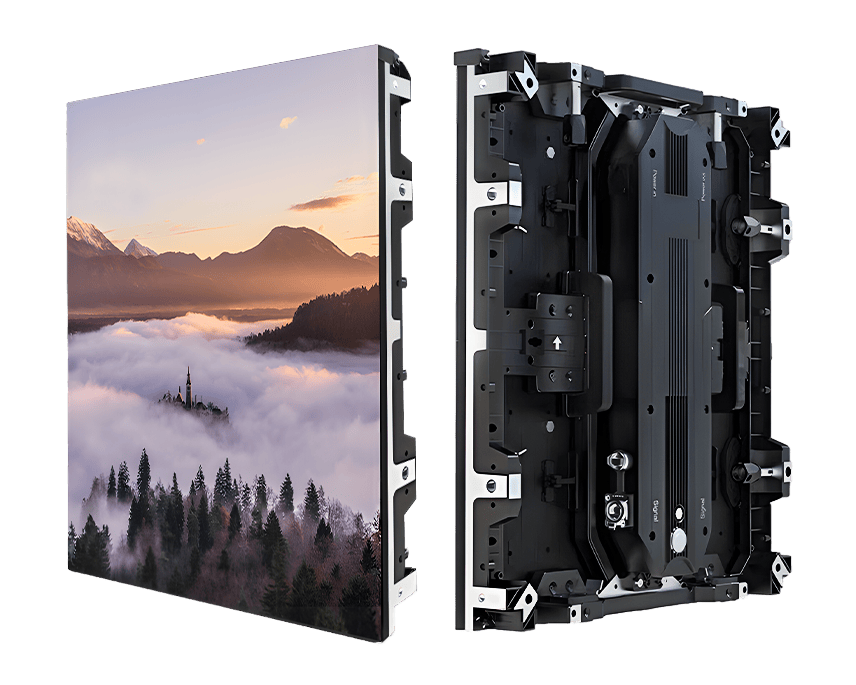

What is GOB LED display?

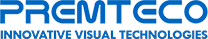

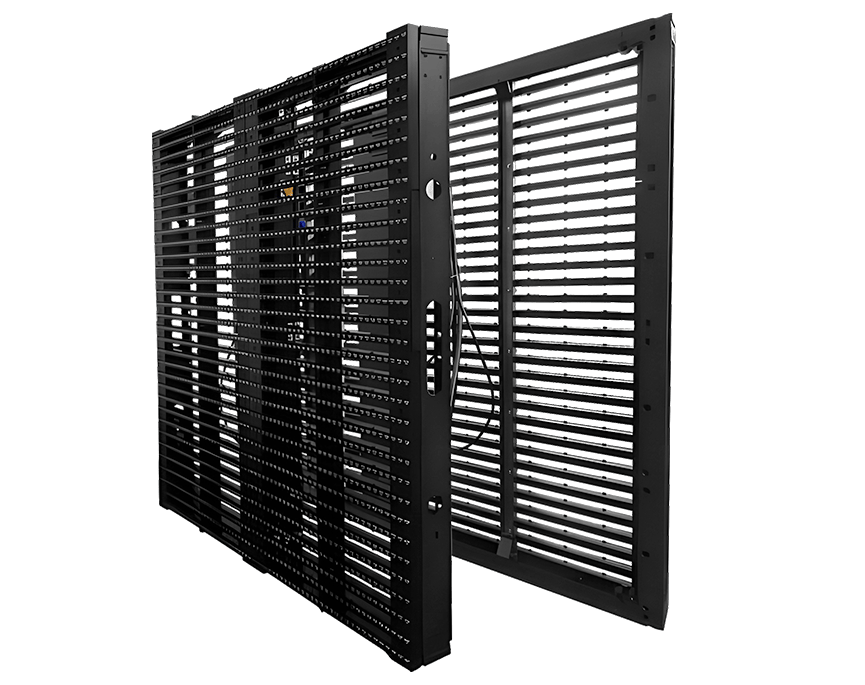

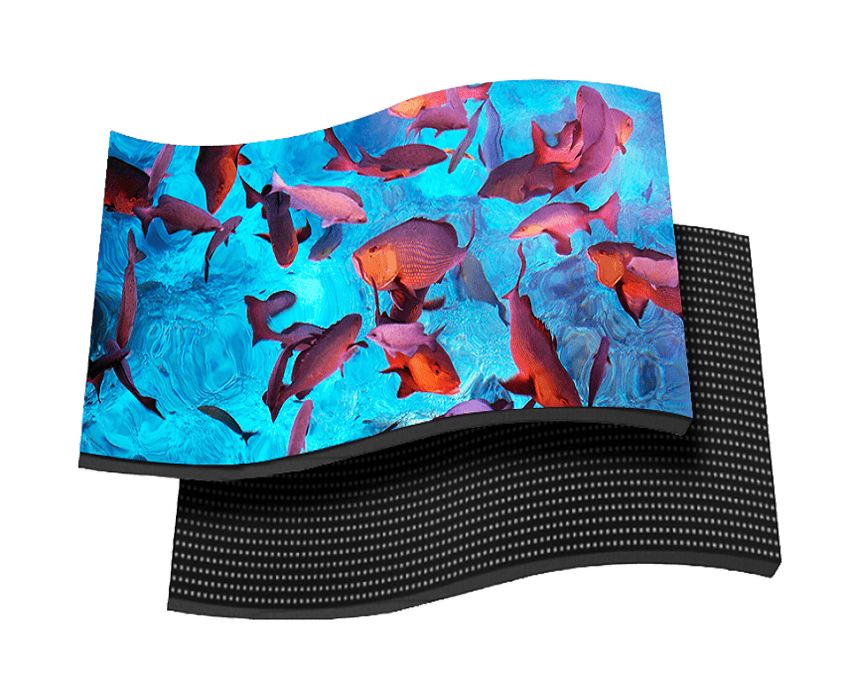

GOB is on-board glue, used to obtain high-protection LED display, this is a new technology, similar to module packaging. It is working with the entire display module (such as 250 * 250mm) by using patented transparent glue to cover the PCB surface of the module. Thousands of SMD lights have been soldered on it, and finally the module has been obtained on its surface. Special shielding layer.

It has a highly protective LED display, which can achieve anti-collision (anti-collision), dust-proof, waterproof, moisture-proof, UV-proof, and will not have harmful effects on heat dissipation and brightness loss. Strict testing over a long period of time shows that the shielding glue even helps to dissipate heat, thereby prolonging the service life.

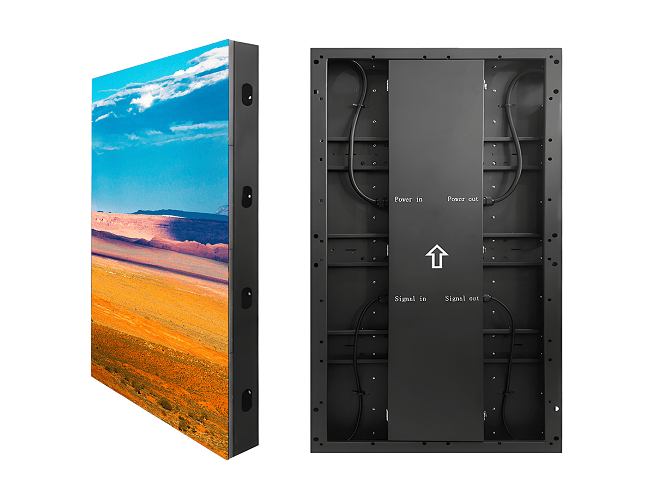

What is COB LED display?

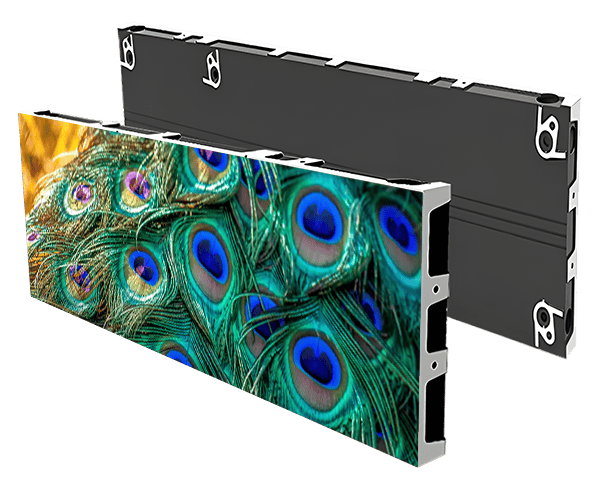

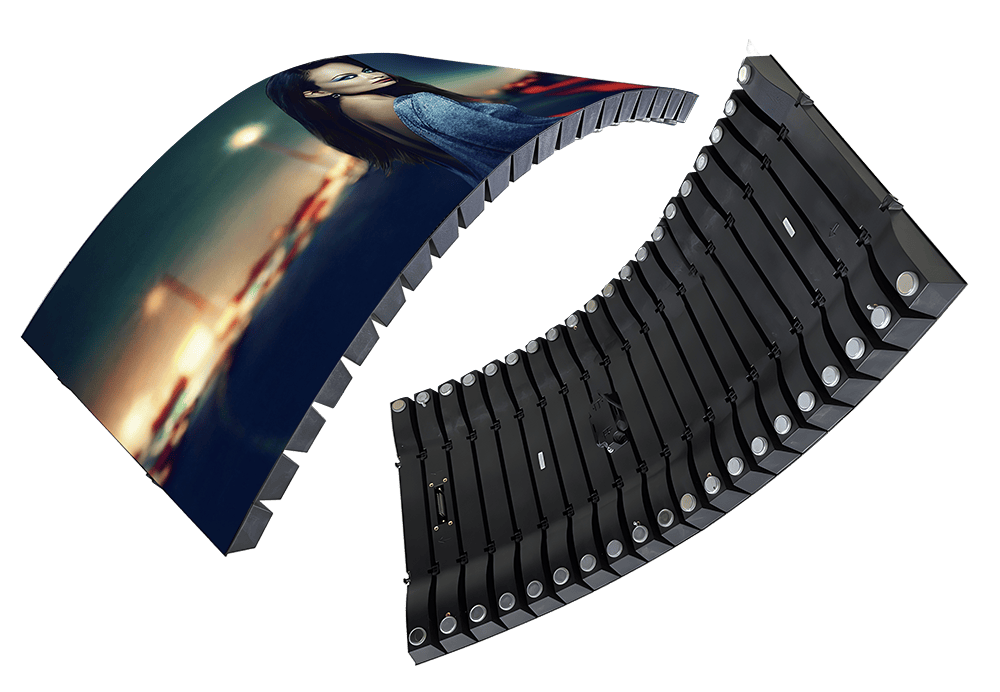

COB is a chip on board, which is a different chip packaging technology. All chips are directly integrated and packaged on a special PCB board. The packaging technology we are talking about is to integrate three RGB led chips into one SMD electronic package.

In a word, COB sounds similar to GOB display technology. But it has a long history of development.

Advantage of GOB

Wide viewing angle, high color uniformity, high contrast, high power efficiency, etc. have the same characteristics as traditional LED technology. The most important thing is to use COB to obtain high protection performance, such as anti-collision, moisture-proof, dust-proof, etc. In short, higher environmental adaptability, this Nanoshi-led coating technology obtains pixel-level protection.

Obviously, GOB technology will also obtain the same high protection display as the goaf. In addition to cost, COB also has risks in terms of wavelength and color separation and the pickup of all chips on the board, which makes it difficult for the entire display to obtain perfect color uniformity.

Although GOB can achieve good color uniformity, and it has the same manufacture and test way as the ordinary modules, the maintenance of GOB is also an urgent problem that needs to solve.

Advantage of COB

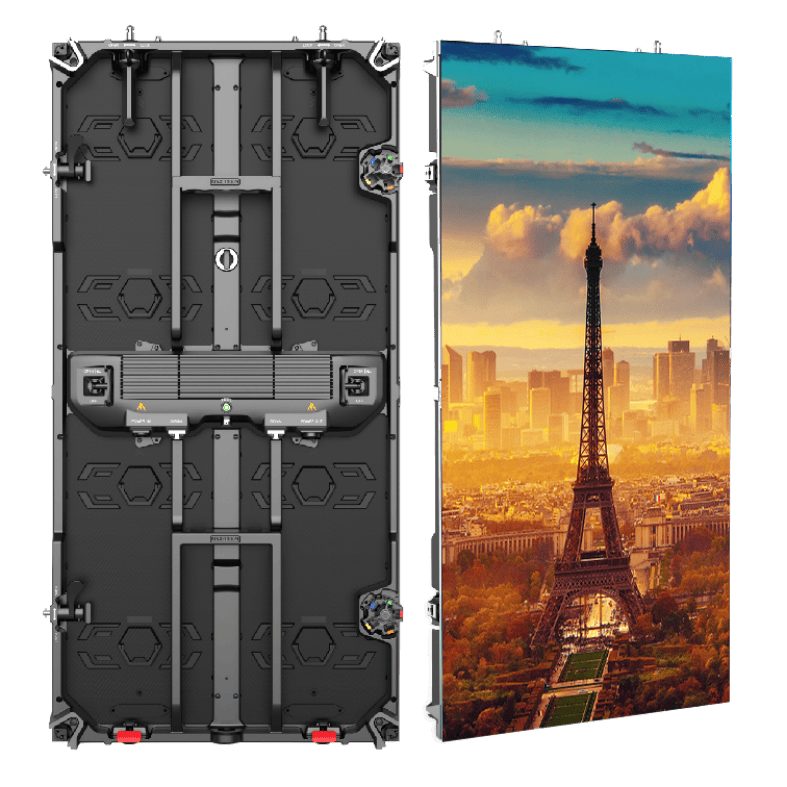

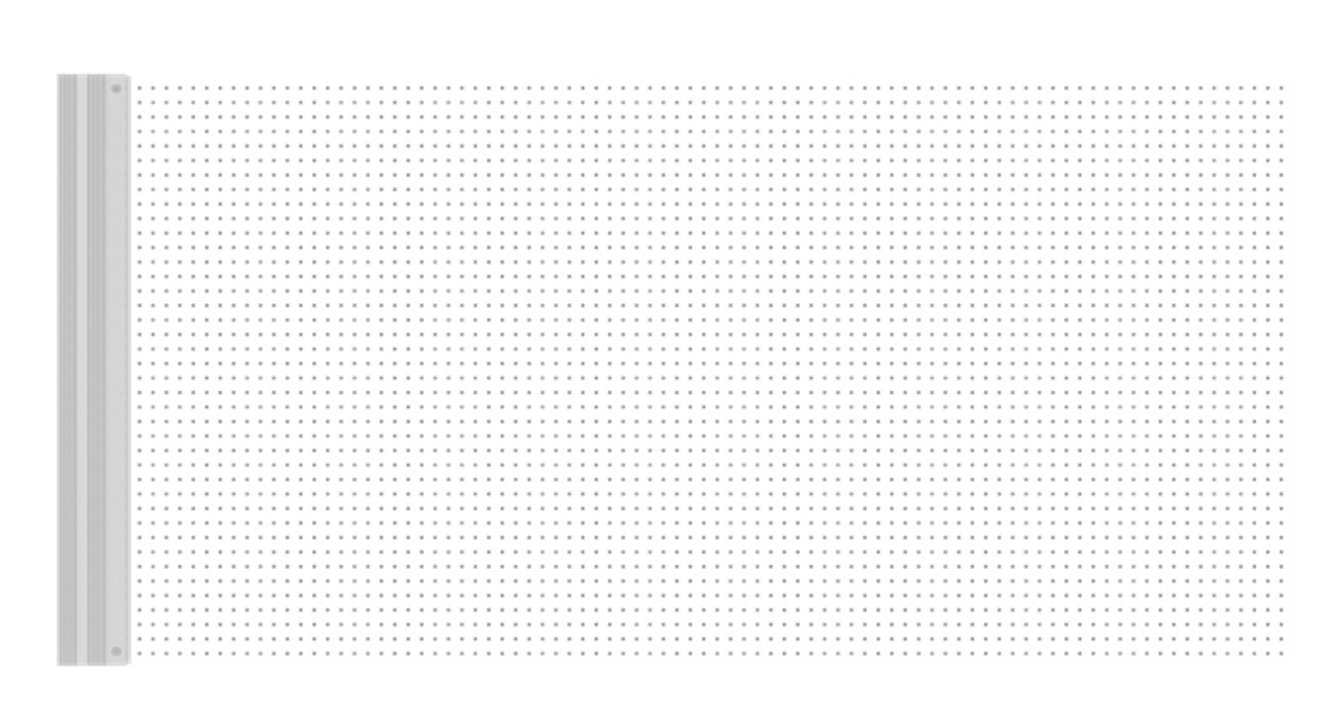

In addition to its own Delta-enhanced COB technology, this technology can also provide high brightness for small-pitch LED displays, three times that of most high-resolution LED displays (up to 3000 Nits). It uses micro LEDs by placing three independent red, green and blue monochromatic micro LEDs on the circuit board.

Due to the small size of the COB LED display, there is no diameter of each LED. This makes the production process simpler and lower cost. COB displays are proud of the heat resistance of high-density packaging.

Compared with SMD and DIP, COB LED is easy to install. Its ultra-thin PCB board can be made into a lightweight LED, which is very convenient no matter where the buyer wants to take it.

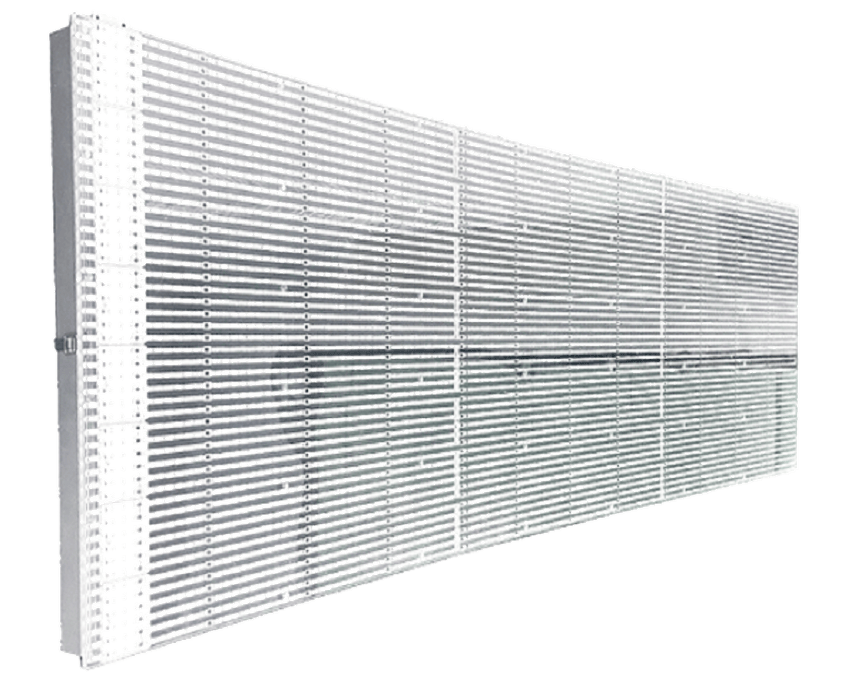

This type of display encapsulates LED chips on a board and cured with the help of epoxy resin.

The best part of a COB display is that it can dissipate heat through the copper foil on the board.

Another important consideration is its anti-corrosion, anti-static, waterproof, anti-oxidation, dust-proof, moisture-proof and other functions, making it an important purchase product for various purposes.

The mainstream display technology in the future is micro-pitch micro LEDs. Theoretically, the pixel pitch can be infinitely small. It is a fine pitch display technology based on COB packaging.

Who are we?

As a professional LED display supplier, we focus on research, design, manufacture, and sale of LED display.

Premteco has built up outstanding reputation in the industry by supplying consistent and reliable LED display products. If you have any question about our company or products, please contact us immediately.