As LED display technology continues to evolve, new innovations like MiP LED display (Micro LED in Package) are gaining traction in both indoor and outdoor applications. Whether you're involved in digital signage, event production, or commercial AV, understanding MiP LED technology is essential to stay ahead of the curve.

In this article, we’ll explore what MiP LED display is, how it works, and why it's becoming a game-changer in the display industry. We’ll also compare it with other LED packaging technologies like COB, SMD, and MicroLED, and highlight its advantages and potential applications.

What is a MiP LED Display?

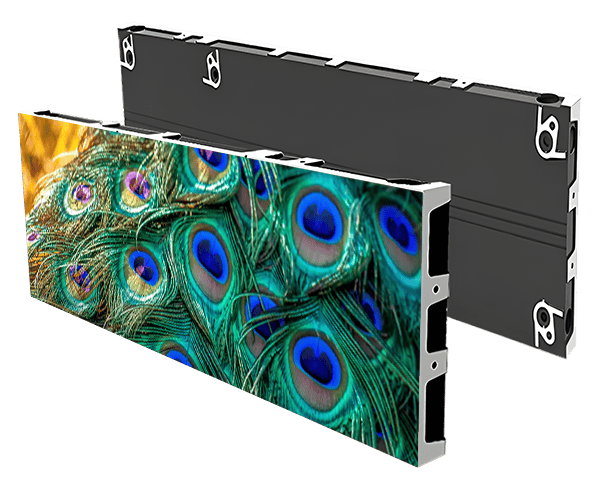

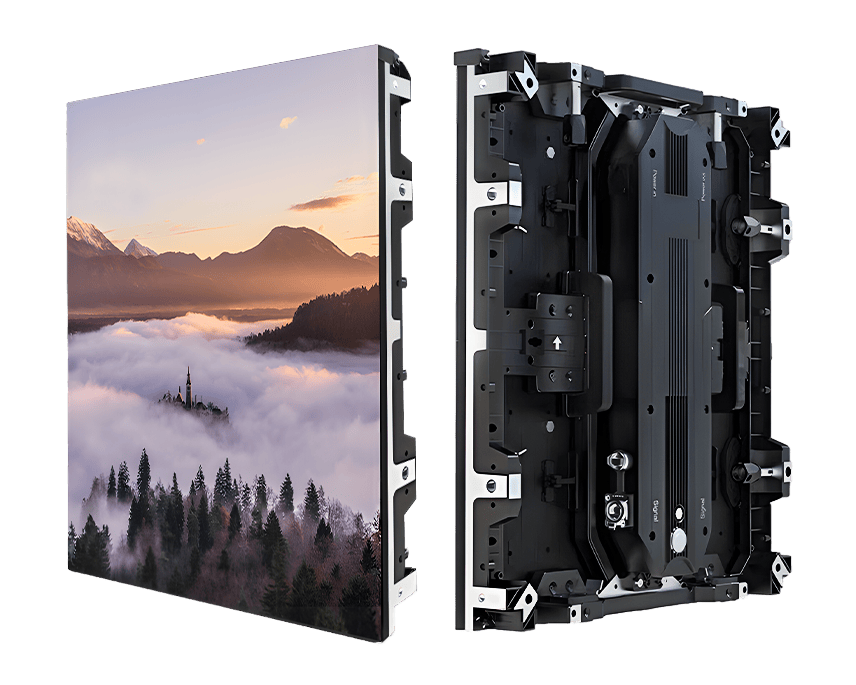

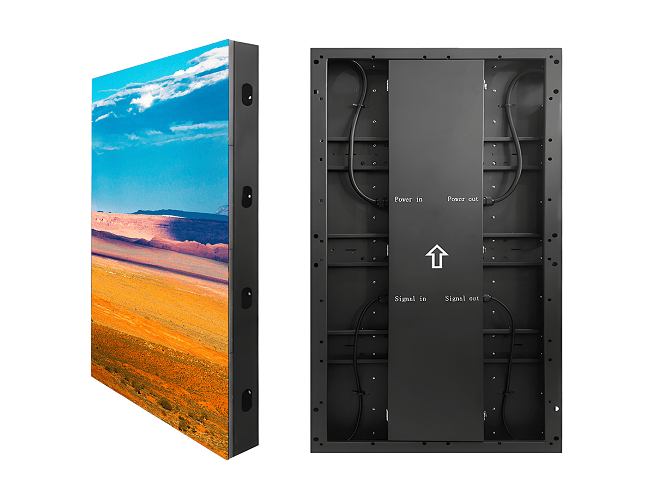

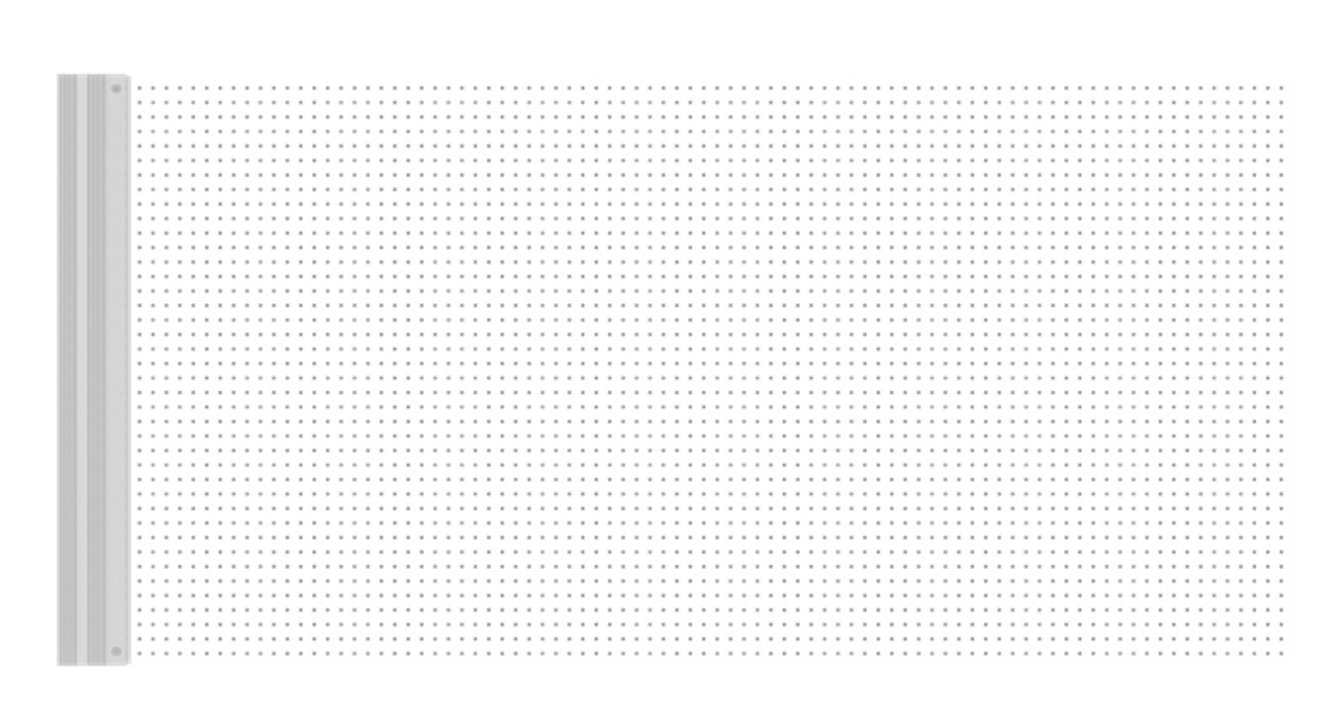

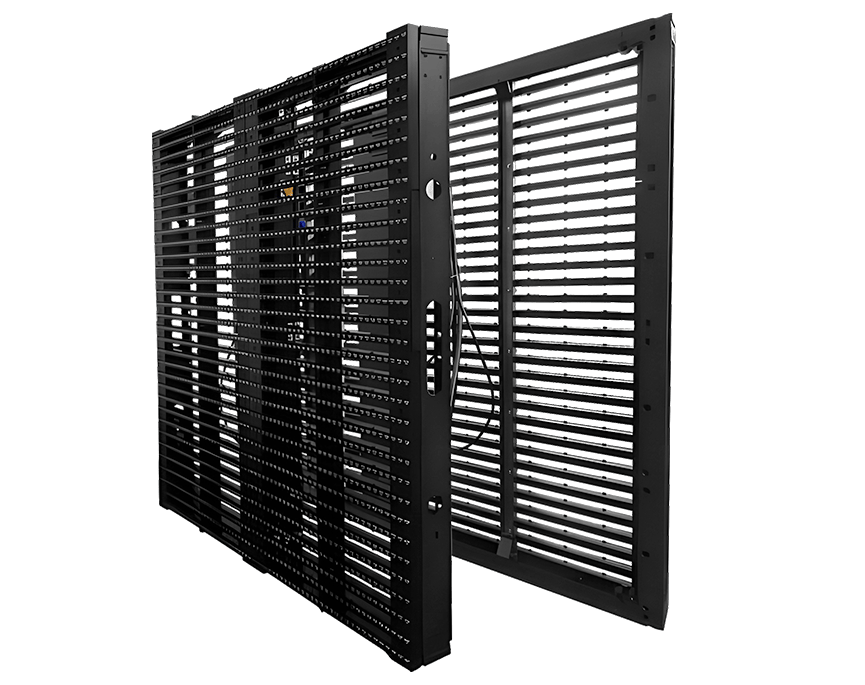

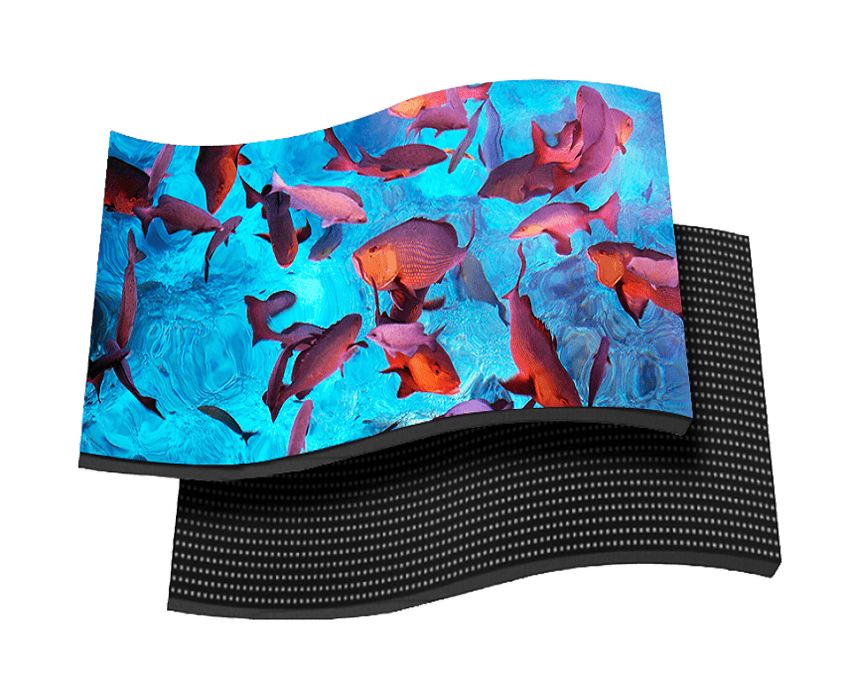

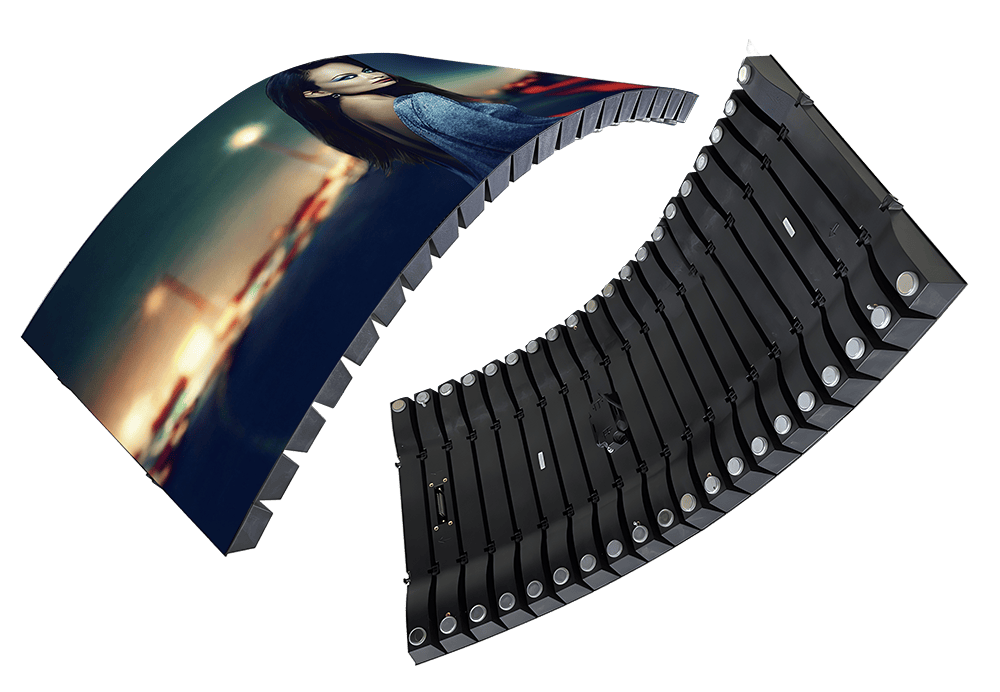

MiP stands for Micro LED in Package, a next-generation LED packaging technology that integrates RGB micro-LED chips into a single surface-mounted package. Unlike traditional packaging methods, MiP allows for the integration of Mini LED or Micro LED chips into a compact, durable module that can be easily mounted onto a PCB.

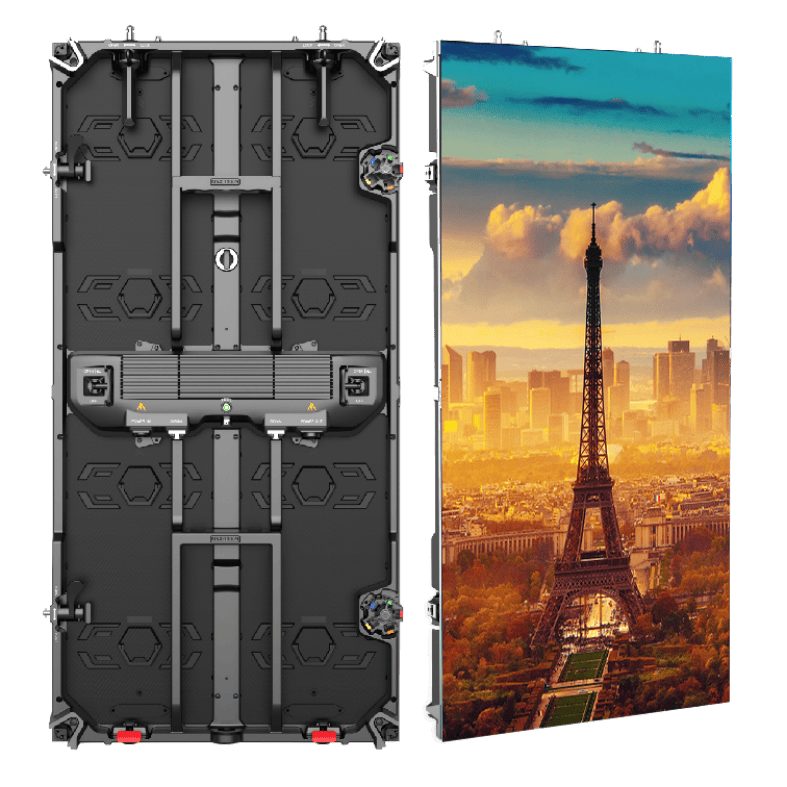

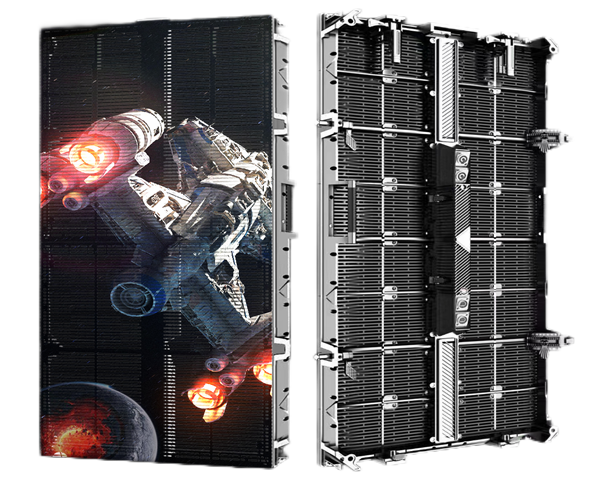

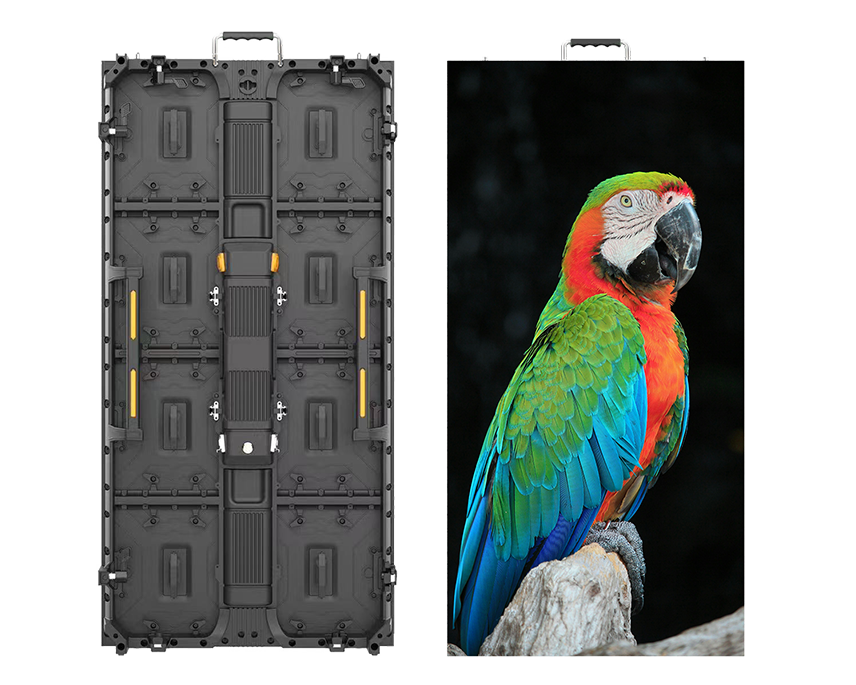

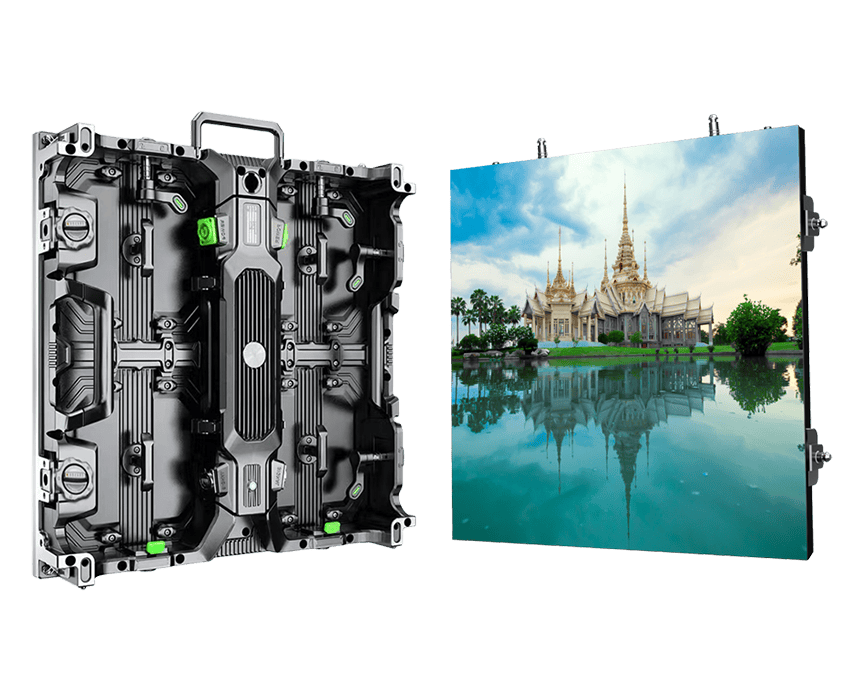

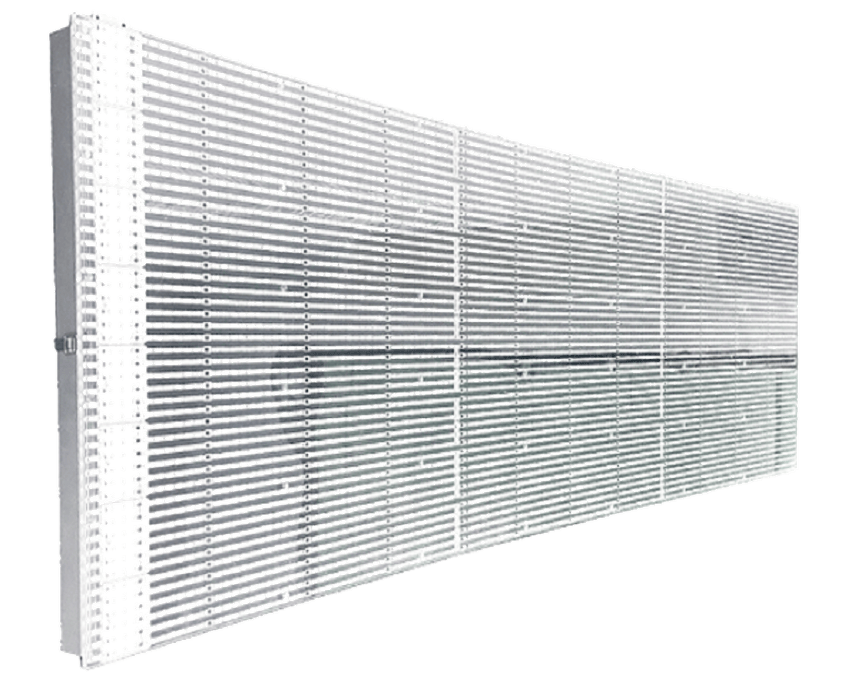

MiP LED display technology is especially popular in high-resolution applications where pixel pitch, brightness, and durability are critical. It’s often used in indoor LED walls, stage displays, corporate boardrooms, and even outdoor digital kiosks.

How Does MiP LED Technology Work?

MiP technology works by taking Micro LED or Mini LED chips — typically smaller than 100 microns — and packaging them into individual pixel units. These units are then mounted onto a PCB substrate using SMD (Surface Mount Device) technology.

Here’s a simplified breakdown of the MiP LED manufacturing process:

-

Chip Preparation: Micro RGB LED chips are prepared using advanced semiconductor processes.

-

Pixel Packaging: Each pixel unit is encapsulated in resin for protection and durability.

-

Surface Mounting: The packaged pixels are mounted onto the PCB using standard SMD equipment.

-

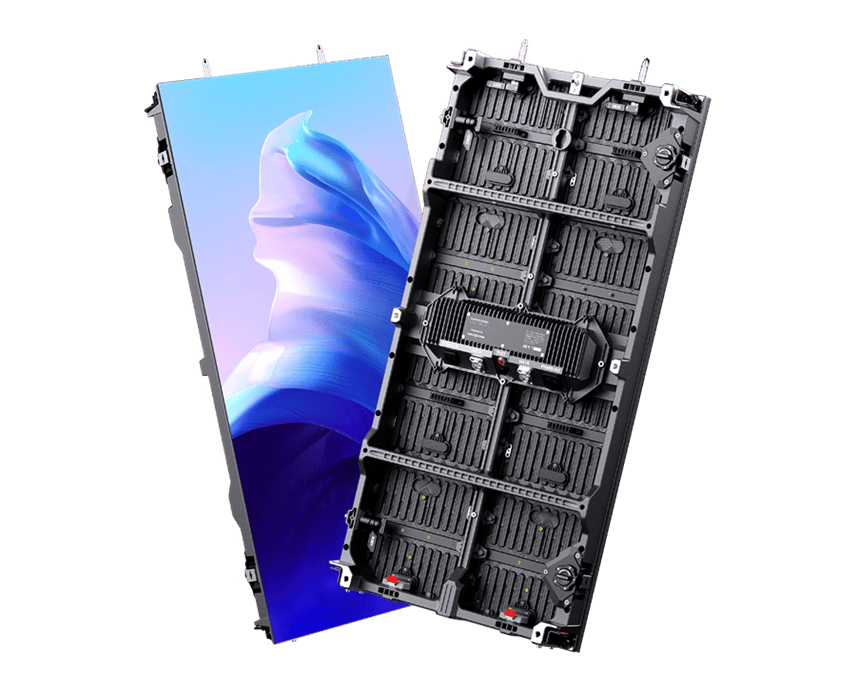

Module Assembly: Multiple pixels are assembled into modules, which are then integrated into the final display.

This process allows for mass production, reduced costs, and greater flexibility in pixel pitch options.

Key Advantages of MiP LED Displays

MiP LED displays offer several distinct advantages over other LED packaging technologies. Here are the most notable benefits:

High Brightness

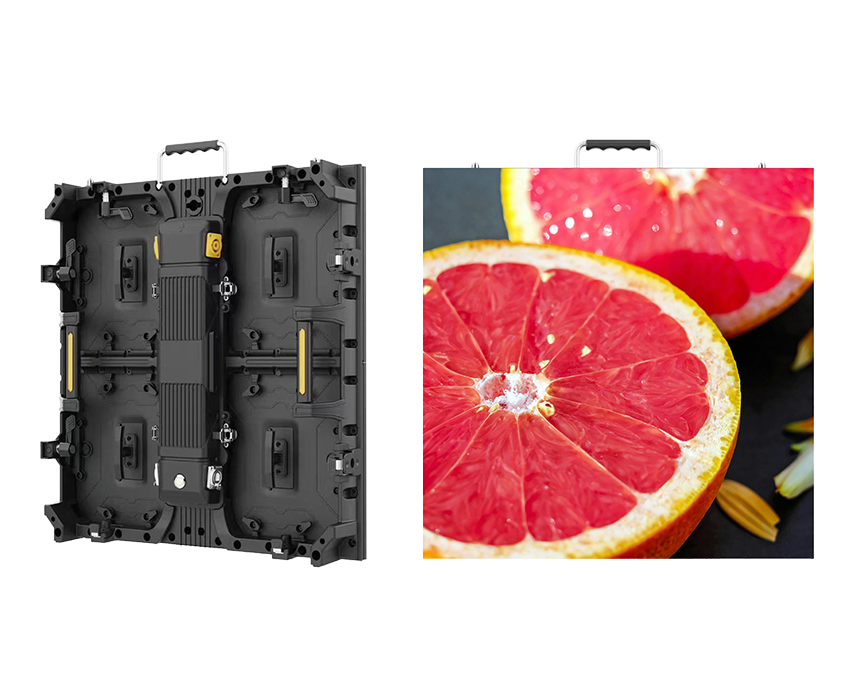

MiP LED displays can achieve brightness levels up to 4,000 nits, making them ideal for high-ambient light environments such as outdoor digital signage and sunlit indoor spaces.

Pixel Pitch Flexibility

Unlike traditional SMD displays that require different packages for different pixel pitches, MiP allows a single pixel package to be used across a wide range of pitches (e.g., from P0.5 to P2.5), reducing production complexity and costs.

Repairability

One of the biggest drawbacks of COB (Chip on Board) displays is their lack of repairability. With MiP LED displays, faulty pixels can be replaced individually, minimizing downtime and reducing maintenance costs.

Durability and Protection

MiP LED pixels are coated with protective resin, offering resistance to dust, moisture, static electricity, and physical impacts. This makes MiP displays suitable for both indoor and semi-outdoor environments.

Better Heat Dissipation

Thanks to the resin coating and advanced packaging, MiP LED modules offer superior thermal management, resulting in lower power consumption and longer lifespan.

Cost-Effectiveness

MiP technology leverages existing SMD manufacturing infrastructure, reducing the need for new equipment investments. It also lowers the defect rate during production and reduces rework costs, making it a more economical choice for manufacturers.

MiP LED vs COB vs SMD vs MicroLED: A Comparison

To better understand where MiP LED technology stands in the broader LED display landscape, let’s compare it with other popular LED packaging methods:

| Feature |

MiP LED |

COB |

SMD |

MicroLED |

|

Pixel Pitch

|

0.5mm - 2.0mm+

|

0.3mm+

|

≥ P1.0

|

0.1mm+

|

|

Brightness

|

Up to 4,000 nits

|

Up to 1,000 nits

|

Medium

|

High

|

|

Repairability

|

Yes

|

No

|

Yes

|

Hard

|

|

Contrast

|

High (25,000:1+)

|

Very High

|

Medium

|

Ultra High

|

|

Cost

|

Medium

|

High

|

Low

|

Very High

|

|

Heat Dissipation

|

Good

|

Excellent

|

Fair

|

Excellent

|

|

Durability

|

Excellent

|

Excellent

|

Good

|

Excellent

|

|

Production Scalability

|

High

|

Medium

|

High

|

Low

|

The Future of MiP LED Technology

MiP LED display technology is still in its early stages, but its cost-effectiveness, repairability, and flexibility make it a strong contender in the future of LED displays.

Several trends are driving the growth of MiP technology:

-

Mass Transfer Technology: Enables the rapid placement of millions of micro LEDs, reducing production time and cost.

-

Integration with MicroLED: As MicroLED becomes more scalable, MiP is expected to serve as a bridge between current Mini LED and future Micro LED displays.

-

Expansion into Outdoor Markets: With brightness levels reaching up to 4,000 nits, MiP is now being adopted for small-form outdoor displays.

-

Growth of Chinese Manufacturers: Companies like PTCLED are investing heavily in MiP production, helping to scale the technology globally.

Find a Professional MiP LED Display Manufacturer

Choosing the right MiP LED display manufacturer is just as important as the technology itself. As a professional LED display manufacturer, we specialize in designing and producing high-quality MIP LED displays tailored to your specific needs — whether for corporate events, broadcast studios, control rooms, or retail environments.

Contact us today via info@ptcled.com to discuss your project, request a quote, or explore how our MiP LED display solutions can elevate your visual experience.

Frequently Asked Questions (FAQ)

Q: Is MiP LED better than COB?

A: It depends on your needs. MiP offers better repairability, higher brightness, and pixel pitch flexibility, while COB provides higher contrast and uniformity.

Q: What is the pixel pitch range of MiP LED displays?

A: MiP LED displays typically support pixel pitches from P0.5 to P2.5, making them suitable for both indoor and small outdoor applications.

Q: Can MiP LED displays be used outdoors?

A: Yes, MiP LED displays can achieve brightness levels up to 4,000 nits, making them ideal for sunlit environments and outdoor kiosks.